Articles

| Name | Author | |

|---|---|---|

| The Next Big Shift in Airline MRO Analytics | Baiju Jacob, Director and Global Head of MRO Practice, and Manuel Fernandes, Digital Subject Matter Expert & Senior Consultant, MRO Practice, Hexaware Technologies | View article |

| Case Study: Making everything work better | John Hancock, Editor, Aircraft IT | View article |

| Case Study: Controlling Aircraft Tooling using RFID Technology | Jakob Heegaard, Director IT, Jet Time | View article |

| Case Study: Innovations in Aircraft Maintenance at easyJet | Gareth Thomas, Application Manager, easyJet | View article |

| Case Study: Using an M&E IT solution to manage CAMO operations | Yuliya Kornyeva, Senior Project Manager, FL Technics | View article |

Case Study: Using an M&E IT solution to manage CAMO operations

Author: Yuliya Kornyeva, Senior Project Manager, FL Technics

SubscribeUsing an M&E IT solution to manage CAMO operations

Yuliya Kornyeva, Senior Project Manager at FL Technics explains using an M&E IT solution to manage different customers CAMO requirements

Let me start this article with a question. Is it really important to use an M&E IT system as used for CAMO to manage a customer’s aircraft? I am sure there are still cases when maintenance for twenty aircraft is managed in Excel and the airlines concerned are happy with that. So does it really matter for a customer whether they get statuses from a sophisticated IT solution or just a plain Excel spreadsheet? In FL Technics we have our own answer to this question based on our experience implementing an IT solution and what this has changed for our customers.

FL TECHNICS

FL technics is a big organization and part of an even larger organization, Avia Solutions Group, an international aviation holding group. We have base maintenance facilities, warehouses and component shops across Europe and Asia. So, as you might imagine, it’s not easy to find IT solutions that fit the needs of everybody in the business. As is common for many MROs and CAMOs, a long time ago FL Technics used to be part of an airline and the connection between base maintenance and engineering is very close. That means common procedures, common business processes and a common IT system. But, over time, FL Technics Engineering has grown and developed a broader scope of services that made it difficult to keep the existing set-up because we were wasting time on procedures that worked for base maintenance customers but were redundant for engineering customers.

THE NEED FOR A NEW SOLUTION

In short, FL Technics was starting to look for a new IT solution. But our requirements for a new solution were straightforward: we wanted…

- To effectively manage our airworthiness data, to accumulate it and to use that accumulated data to support future customers. We also wanted to propagate existing data for new aircraft and to save time, making us more effective.

- To have separate business processes for CAMO and Engineering operations and to establish our user policy.

- To share results with customers; we already had a homemade solution that aggregated data from the legacy system and put it into a customer portal but that was really time consuming because it took ages to introduce a new report to the customer portal. So we wanted something new, an all-in-one solution for airworthiness management and customer reports.

- We also wanted a flexible and easy-to-use solution.

FINDING A NEW SOLUTION

We started to look for the new solution but discovered that we didn’t process in the same way that many presenters did; however, we finally found a good solution from Commsoft that fitted our needs. We signed a contract with them before Christmas 2013 and got credentials to the database at the start of 2014. However, at that point, our implementation journey had only just begun. We were very keen to have all our customers’ data in the system as soon as possible but we didn’t know how to do it so hired a group of independent consultants and asked them to enter the data to the new system. They used the system and its functionalities, working very fast, but when our engineers started to maintain the first few aircraft in the new system, they were not very happy. As they explained the problem, the devil was in the details; so what was wrong?

They couldn’t form proper statuses from the data we had; some of the data was not put in to a standard that matched our standards, some of the data was missing and some of it was taken from the legacy system but was not very good quality. So we made a lot of effort to manage the data in the right way but we continued to use the system intensively during that year and, at the end of 2014, we were ready to form our own implementation team.

By the end of 2015, the following year, we had achieved the full end results having dealt with 14 aircraft, in nine maintenance programs covering six aircraft types. Also, we established new procedures in our Continuous Airworthiness Management Exposition and got approval for OASES as our official system in FL Technics.

What that means is that, for future customers, we can implement aircraft very fast: it takes us around two weeks now to implement one aircraft of a type that we already have in the system.

Figure 1

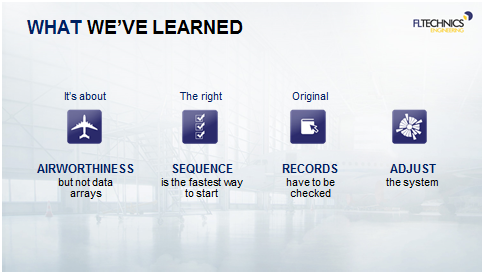

LESSONS LEARNED

During this implementation process we learned a great deal (figure 1): first about having the right approach to the data because it’s not about the data arrays, it’s about how the data can be used to support airworthiness. We need the data but not just as an entry in the database; it should help us to prove the airworthy condition of the aircraft. Also, the sequence in which we enter the data really matters because some data becomes obsolete very quickly and we have to update this data constantly. So entering in the right sequence really helps to use the data in the system in the very early stages of implementation. Also the sources of data should be checked, the original records, and here engineering expertise really matters. It’s also good to know all the functionalities of the system and how to adjust it to our processes; how to use it effectively.

LEVERAGING THE IT SOLUTION FOR THE BUSINESS

New capabilities and more scope for services

Through implementing OASES, we got the leverage for our business that we needed and we also gained a new capability that we can share with our customers. First of all, we now know the fastest way to start continuous airworthiness management in the system. Also, we have ready-to-use data for popular aircraft types that we can propose to our customers and that we can use. We have a dedicated team of engineers who can verify the data and prepare the right statuses that would satisfy every auditor. And we know which questions should be asked of the team and the organization to set-up the processes and configure the system in the right way.

Figure 2

In figure 2 you can see the standard range of services that we are undertaking in OASES and we are very happy that working with Commsoft has enabled us to further broaden this range of services. For instance, this year we were happy to get a functionality that lets us form an Avionics equipment list and Software list in the system which is great. But, even with a perfect solution, it’s not easy to satisfy all customers.

Different customers have different needs

Different customers have varying approaches to the data they want and to the level of involvement that they want with the process. Some customers are happy with full CAMO support; when they get their statuses and do not want to be involved in the processes of airworthiness directives, etc. But other customers, especially when they have personnel able to control or to perform certain functions, prefer to involve their own personnel in the process. For example, one customer wanted their personnel to enter their technical logs for different defects and component changes directly into the system. The final customer type are the ones that want to establish their own CAMO; that’s our ‘favorite’ type of customer because they know what they want and they are very motivated, so you can imagine how demanding they are.

What the solution enables us to do

Luckily, we have a few options that can be adjusted to meet the requirements of all these different types of customers. First of all there is the system itself; for customers who use FL Technics for CAMO support we keep their data in our own system: but for those that want to have more control it’s possible to use a separate database and they can establish their own site. However, in this case, the customer needs to put some investment into hardware, to security and to back-up. Another option is the private Cloud; it helps to eliminate the investment costs and Commsoft can propose this option as well.

There is also access to the system. If the customer is happy with the statuses and report in read-only access, it’s possible to organize that, via RDP (remote desktop protocol) connection and actually that is the same way that our engineers use the system when they working remotely, rather than from the office.

But if the customer wants more involvement, it’s possible to give access to certain functionalities and it’s our choice how to set up those functionalities so the system is very flexible and we can choose what menus the customer can use.

Also, we can propose training: we have an experienced team and can train the customer to any level. A good additional facility here is that we can train customers remotely via Skype and also can engage the Commsoft team for training purposes.

Overall, our system has very good support because Commsoft Service desk is available 24/7 and also the FL Technics team can support any customer with engineering expertise.

IMPLEMENATION

Figure 3

The initial stage (figure 3) is applicable to customers who want to have their own system. In the early stages, Commsoft configures their server and installs the system and then they import the base data that we have collected during our years of operation for whatever type of aircraft the customer has. Once all that is completed we can create new users for the customer (figure 4), induct the rest of the data for the aircraft and then perform training for the customer to explain how to use the system, how to access it and how to generate statuses they need.

Figure 4

SUCCESS STORIES

Donavia

This is an interesting example because we managed to do everything remotely. Donavia used to be our long-standing customer and, luckily, the decision to go towards their own CAMO coincided with our decision to switch to another engineering and maintenance system. We organized a separate database for them, Commsoft transferred all the data for ten aircraft that were already in OASES to the new system and we provided a few training sessions. It was a very interesting experience because we had on one side the Commsoft team based in the UK and the FL Technics team based in Vilnius plus the Donavia team in Rostov-on-Don. To give our customers more comfort, we translated the regular training sessions from English to Russian in real time. We had these regular training sessions for about a half year, then Donavia was able to establish their own CAMO that passed audit and managed their own aircraft by themselves.

Somon Air

Somon Air became the first direct customer of Commsoft in Central Asia. They had been a long standing customer of FL Technics but we had managed only one aircraft from their fleet of six. However, after we recommended OASES as a good system and switched to this system ourselves we were awarded a contract for the rest of the Somon Air fleet. They have chosen to have their own server and have opted for a private Cloud. We trained their team with one week’s training at their base in Dushanbe in Tajikistan including the initial training on how to use the system, what are the functionalities… and then after the training, the Somon Air team was able to join our team in simultaneously implementing the data to the system. Then, after a few times, when they needed more expertise, our engineers went to Dushanbe for three weeks which was also very interesting. The time coincided with an audit in Somon Air and not all the data for their aircraft was there but the Airworthiness Directive status that our engineers generated from the system helped them to pass their audit. So, it was really helpful and the sequence in which we had put the data in the system was the right one.

WHAT MATTERS FOR CUSTOMERS

So back to the question that I posed at the start of this article, ‘Is it really important to use an M&E IT system as used for CAMO to manage a customer’s aircraft?’ The answer is that what matters for the customer is the possibility to access their aircraft data regardless of time and location, understanding and involvement with a continuing airworthiness management process that only specialised M&E IT system can provide. The combination of the perfect IT tool with engineering expertise, experience and total dedicated team support is also important because it reassures the customer that they’re among supportive, competent and well informed friends.

Contributor’s Details

Yuliya Kornyeva

Yuliya Kornyeva is a Senior Project Manager at FL Technics leading the software solutions implementation team. Her aviation career started six years ago as a Line Maintenance manager. In 2013 she joined FL Technics to pursue her interest in IT projects and databases, successfully managing the transition to a new M&E system and now, with a team of experienced engineers sharing the expertise with FL Technics’ clients. She holds an MSc in Instrumentation Engineering and, before entering the aviation industry, worked as a design engineer and assistant lecturer at the National Technical University of Ukraine.

FL Technics

FL Technics is an aircraft maintenance solutions’ provider, serving customers from Europe, Asia, the Middle East, as well as Africa and Latin America. The company’s infrastructure includes an extensive network of Base and Line Maintenance support across Europe and Asia Pacific. FL Technics is an EASA Part-145, Part-M, Part-147, Part-21 certified company, serving a wide range of Airbus, ATR, Boeing, Embraer, Sukhoi Superjet and other types of aircraft.

Commsoft

Commsoft was formed in 1973 and has developed specialist software for the aviation industry, including OASES. The product is constantly developed by an in-house team who understand the aviation and aerospace business from having previously worked for airlines and OEMs. This industry knowledge ensures that products meet users’ needs and match the latest industry developments. Commsoft provides worldwide technical and implementation support through a network of offices in the UK, India and Australia.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.