Articles

| Name | Author | |

|---|---|---|

| The Next Big Shift in Airline MRO Analytics | Baiju Jacob, Director and Global Head of MRO Practice, and Manuel Fernandes, Digital Subject Matter Expert & Senior Consultant, MRO Practice, Hexaware Technologies | View article |

| Case Study: Making everything work better | John Hancock, Editor, Aircraft IT | View article |

| Case Study: Controlling Aircraft Tooling using RFID Technology | Jakob Heegaard, Director IT, Jet Time | View article |

| Case Study: Innovations in Aircraft Maintenance at easyJet | Gareth Thomas, Application Manager, easyJet | View article |

| Case Study: Using an M&E IT solution to manage CAMO operations | Yuliya Kornyeva, Senior Project Manager, FL Technics | View article |

Case Study: Making everything work better

Author: John Hancock, Editor, Aircraft IT

SubscribeMaking everything work better

John Hancock explains how Petroleum Helicopters International gained and continues to enjoy the best results from their MRO IT solution

THE VALUE OF SHARED EXPERIENCE

There is nothing so real as the experience of others working in the same field. This case study shares an experience with which any MRO operator will be familiar. It’s the story of US helicopter operator Petroleum Helicopters International (PHI), one of the world’s leading helicopter services with operations in 43 countries and 77 field bases around the world. Starting from how they assessed their MRO IT requirements and concluded that those requirements could best be met using a powerful end-to-end MRO solution, to how they found the right IT partner and worked together to implement the system, improve business processes and manage the change needed to streamline their maintenance operations.

PHI INC. WORLD CLASS HELICOPTER OPERATOR

The maintenance process is at the heart of PHI’s unwavering commitment to safety, which can best be described in a mantra often heard around the company’s maintenance hangars; every employee believes they can reach ‘Zero’… zero scope for error in safety issues. As a leading helicopter service provider to the global oil and gas, onshore mining, air medical and technical services industries, PHI places a high premium on its reputation, and the trust that customers have in the services, in the people and in the machines that deliver those services. From 1949, when PHI first identified helicopters as the ubiquitous transport solution that they are today, the company has become a reliable service provider in the sectors where it works. That reliability is founded on the expertise of pilots, maintenance technicians and every other employee – all committed to delivering wonderful customer satisfaction through exemplary safety and high quality helicopter provision.

With trust, quality and professional excellence at the heart of the business, PHI is proud that many employees have been with the company over multiple years (some more than thirty years). This depth of experience supports not only the zero error safety ethos but also the whole attitude where every employee feels responsible for and is proud of the quality of PHI services. It was in the context of this ‘safety and quality first’ culture that PHI determined in 2003 that they needed an MRO IT solution to see the company into the future delivering helicopter transport, around the world, in all conditions from Antarctica to Middle East deserts.

PHI’s NEED FOR AN MRO IT SOLUTION

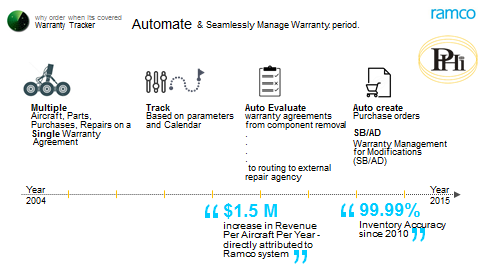

The timeline for PHI’s project

From first establishing PHI’s MRO IT goals, in 2003 the business embarked on a rigorous process to select a partner who could meet current needs and work with the business as it grew into the long-term future. Those current needs generated multiple challenges in managing high levels of expertise and timeliness of support in a seamless process that was and is very reliant on reliable data. For all of these reasons, the need was to find a solution provider who could work as a partner with the company, not just a software vendor. All of this crystallized into PHI’s original goals prior to the selection process – they had business requirements and also wished to realize the benefits that would accrue from a new system.

PHI’s goals – the start of everything

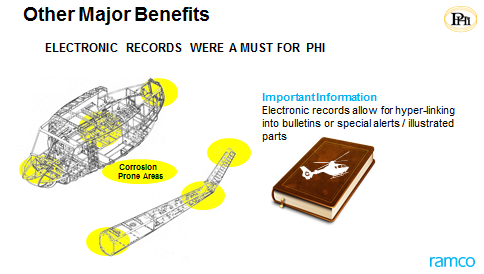

The overall goal was to achieve the benefits of an end-to-end solution that would streamline the entire workflow and enable PHI to remain at the forefront of its sector, as technology and systems developed in future. It was also important to find a partner who understood the aviation business. The solution would need to be able to reduce every possible source of revenue leakage, helping to deliver on time and stay in budget; plus the capability to accurately capture data at source, at all levels, avoiding data duplication and introducing data validation to avoid junk data from polluting the system. It had to be a robust system that could work with, monitor and audit vendors to ensure equitable collaboration. Plus, it needed to offer a significant level of automation of routine transactions, essential for the smooth functioning of the system, but time consuming minor, regular activities that ate into resources. The chosen solution would have to help achieve operational efficiency with simplified processes, e.g. having the right parts, at the right place, at the right time, with the right quality. Other requirements included a secure and transparent system that would help track status, data, and performance with accuracy at any point in time and that would help the company go paperless – from electronic record keeping to electronic signature and barcoding. This was a must for PHI to ensure that records would allow hyperlinking into bulletins or special alerts and illustrated parts catalogs, and also help reduce costs while improving the quality of documents and records.

Finally, PHI needed a strong process monitor that would cognitively forecast events within the system and warn users in case of any process deviation.

In short, PHI was looking for a complete solution to ensure a continuing return on investment (ROI), at implementation and into the future.

What PHI needed from an MRO IT solution

- An end-to-end solution;

- To reduce revenue leakage;

- To accurately capture data at source;

- To support collaboration with vendors;

- Automation of routine transactions;

- Efficiency through simplified processes;

- To be secure and transparent;

- Support the move to paperless processes;

- To be able to forecast events.

Selecting the right IT partner

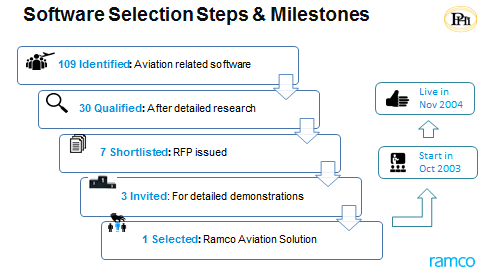

With all of the expectations that PHI had brought together, there would need to be a rigorous process to find an IT system provider with best fit of solution, to match PHI’s requirements and with an organization and culture compatible with the helicopter operator’s own organization and culture. Selection was a business process in its own right (figure 1) for which a selection team was brought together.

Figure 1

With everything now clear, PHI took the first step; identifying 109 developers and vendors of aviation related software. Detailed research against the criteria of the company’s expectations and requirements saw the number of candidates whittled down to 30, who might be qualified. A further short-listing process saw the number reduce to seven shortlisted vendors, who were sent Requests for Proposal (RFP) based on the responses to which, PHI selected three candidates who would be invited to make detailed presentations to the company.

Those presentations offered a unique assessment criterion. Each department at PHI had to provide a demonstration script representing a common situation they faced regularly on the floor. The last three vendors were each allocated two days in which they could make their presentation, based on the above ‘common situation’ material, a familiarization visit to the company and a common set of demonstration data was provided to each shortlisted vendor. PHI also shared with each vendor the scoring criteria that would be applied. When all three vendors had made their presentations the PHI team spent one day scoring for each vendor, with each department team scoring the corresponding demonstrations presented by the potential partners based on the elements they wanted to see in the software before compiling all the scores and selecting one vendor.

At the end of that process, the PHI team arranged to meet some clients of the selected vendor before taking their recommendation to the PHI steering committee, to finalize the selection and then communicating the results of the process to the project sponsors in PHI for final confirmation. From this thorough process, PHI selected Ramco Aviation Solutions as the vendor who most closely matched their needs with out-of-the-box solutions to the ‘common situations’ and could deliver the end-to-end solution that the company needed.

THE IMPLEMENTATION

As with selection, implementation of the new solution was a process in its own right. Four critical success factors were identified as managing change, managing expectations, keeping to schedule and cost, and the relationship between the new system and the MRO workforce. The implementation process itself was broken down to five key elements, to ensure a smooth and transparent transition.

Developing the project charter

The project charter was the rulebook that had to be adhered to without deviation and could be referred to in support of both PHI and Ramco in taking crucial decisions, during implementation. It defined all the key elements of the process: the project objectives and the delivery model as well as the project deliverables themselves. The project organization was set out with the roles and responsibilities within it, and project communication structures plus documentation standards were also included. Mechanisms were established for project reviews and, importantly, for issue resolutions where required. At a higher level, the change management policy and processes were defined and risk management was undertaken.

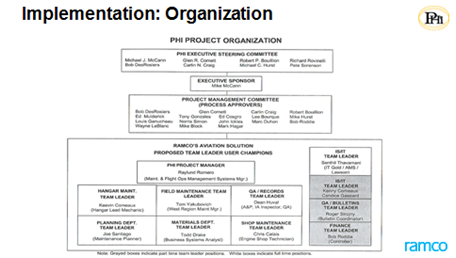

Organization with clear role allocation and a top-down approach

The top-down approach helped get buy-in from every employee at PHI and ensured that all members of the team were aware of their contribution towards this significant transformation and, for this crucial step, the best performers were chosen. For every lead defined at PHI to take up responsibility for a specific element of the implementation process, a corresponding Ramco member was also identified. Those members drawn from the PHI and Ramco teams interacted directly with each other for all aspects of the allocated element (figure 2).

Figure 2

Clear channels of communication

Communication (verbal and non-verbal) was key to success at every stage of implementation. To ensure clarity, the use of jargon terms or potentially confusing language was kept to a minimum. This ensured that every aspect of the implementation was communicated clearly between all the stakeholders across PHI and Ramco’s teams.

Solution delivery in phases

The phased delivery schedule worked efficiently in overcoming the biggest challenge of ‘data cleansing’ by isolating every data element and validating them, before including them as part of the new solution.

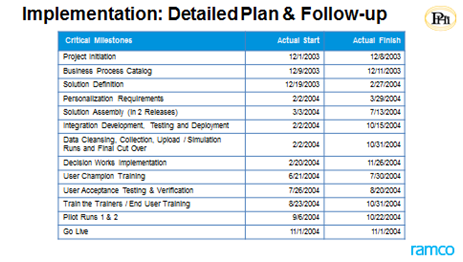

Regular follow-up and on-schedule delivery

Ramco worked closely with PHI at every step of the implementation providing detailed plans at every stage, including the number of people required and the total time taken. As can be seen from figure 3, the follow-up recordings were meticulous to quickly identify where any delays might have occurred.

Figure 3

Every deviation from plan was discussed in detail with all stakeholders and documented before implementation.

Change Management

In a sense, there were two types of change management. The first and most commonly referred to was the management of change, as it affected people in the business. What this boiled down to was communication and respect. The person bringing the change and the person whose work would be affected by the change had to engender strong bonds of mutual respect, so that neither of them would think that the other might be leveraging some aspect of the new situation to gain an advantage. The prerequisites for that respect were trust and transparency (nothing should be hidden). Strategic alignment, linking the business’s resources with its strategy, ensured that everybody understood not just what they had to do but how that would contribute to the overall success. And, finally, a partnership approach meant that people would be working with the company, not for the person introducing the change.

The other sort of change management was more prosaic; to ensure that any necessary changes in the implementation did not result in the system going right back to the original position, from which the program was working to get away.

POST-IMPLEMENTATION AND THE IMPACT ON THE BUSINESS

With the new system implemented and running by November 2004, the big question then became, what impacts did the changes bring about in the key operating areas of PHI’s MRO function: materials, maintenance, planning and reliability?

Material impact

With the Ramco system in place, replenishment planning and materials forecasting has evolved as a robust system with cognitive abilities and every transactional process from repair order processing to contract purchasing has been simplified. The vendor certification process was streamlined, with provisions to place defaulting vendors on hold automatically and schedule regular vendor performance audits. Also, the Collaboration Manager established business-to-business connectivity and automated regular transactions, thus ensuring savings for PHI. Another time saver was the auto-generation of POs the moment any part reaches ‘min’ to replenish the stock back to ‘max’; this removed unnecessary manual intervention for many regular transactions. Also, the request matrix simplified the requisition process using an algorithmic approach to suggest auto-solutions. And, last but not least, warranty management (see Figure 4) to prevent revenue leakage by monitoring the warranty terms.

Figure 4

Maintenance impact

The implementation of paperless processes at PHI saved time, trimmed the processes and was greeted with immense relief by mechanics, who no longer had to refer to loads of paperwork, for a simple inspection. The introduction of electronic signatures ensured authenticity, while barcoding helped eliminate keystroke errors and increased process speed, at each stage. Electronic record keeping and data entry at source has helped in data validation, analytics and security; avoiding data duplication. Easy referencing and robust process documentation were ensured with Document linking; plus, consolidating page views by providing multiple options in a single screen also increased compliance.

Planning and reliability impact

Cognitive solutions helped forecasting and planning to avoid unnecessary spends and set automated reminders. Also, a single data repository (as opposed to 13 separate databases previously) helped avoid data duplication across various databases. Discrepancy recording – AOG (aircraft on ground), MEL (minimum equipment list), incident occurrences, etc. – was made easier with the Ramco system and single entry of data at source helped eliminate redundancy from multiple entries of the same data. Improved data reliability also supported reports and graphs – MTUR (mean time between unscheduled removals), MTBF (mean time between failures), aircraft availability, etc. Overall, effective planning solutions helped achieve 100% automation in PHI’s inventory procurement process.

WHAT THE END-TO-END MRO SOLUTION ACHIEVED FOR PHI

The implementation of an end-to-end MRO solution, more than ten years ago, has supported PHI in achieving a secure, simple, scalable, collaborative, and streamlined process. The partnership with Ramco has helped PHI consistently improve its services, to become an industry leader in managing operations, technology, and maintenance. The adaptability of the solution has supported the operator in providing a flexible configuration, to meet the requirements of each vertical (from the oil and gas industry to medical operations) and cater to the unique climatic conditions in each country, where the business operates.

Most importantly, the numbers speak for themselves. PHI has seen a $1.5m increase in revenue per aircraft per year. Since 2010, the company has achieved an inventory accuracy of 99.99% with physical inventory audits reduced from four days to four hours and, leveraging better more accessible data, 20% of repair expenses are now recovered in warranty. There has been a 50% reduction in turn-around times for major refurbishments, at the same time that the fleet has grown from 205 to 265 aircraft and yet, there has been no increase in manpower numbers except for direct crew.

PHI has learned through profitable experience the benefits to be gained from identifying what was needed from an MRO IT solution, undertaking a thorough process to identify the right technology partner and then working together over the long-term. In that way, they have ensured that the business is always properly equipped to face whatever challenges might arise and take advantage of any opportunities, in other words, be successful.

Contributor’s Details

Ramco

RamcoRamco Aviation Software is a leading solution of choice for Airlines, Operators, OEMs and MROs in Civil and Defense aviation across the globe. Headquartered in Chennai, the company has 21 offices spread across India, USA, Canada, Europe, Australia, Middle East, South Africa and APAC. Ramco focuses on providing innovative business solutions that can be delivered quickly and cost-effectively in complex environments. It is a fast growing enterprise software player disrupting the market with its multi-tenanted cloud and mobile-based enterprise software in the area of HCM and Global Payroll, ERP and M&E MRO for Aviation. Ramco Systems focuses on Innovation and Culture to differentiate itself in the marketplace. On the Innovation front, Ramco has been focusing on moving towards Cognitive and Robotic ERP.

Petroleum Helicopters International

Petroleum Helicopters InternationalPetroleum Helicopters International (PHI) Inc. provides helicopter transportation and support services. The company is based in Lafayette, Louisiana and is one of the world’s leading helicopter services with operations in 43 countries and 77 field bases around the world. Since PHI’s inception in 1949, the company has operated and maintained a wide variety of aircraft. From the Bell 47G to the innovative airframes of today, PHI has flown virtually every type of commercial helicopter. In addition to flying aircraft, the company has also maintained its own fleet during that time. Safety, service and operational performance are the company’s top priorities. This focus drives the company and offers customers total service, service from the company that created the standard for operating helicopters–The PHI Standard.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.