Articles

| Name | Author | |

|---|---|---|

| The Next Big Shift in Airline MRO Analytics | Baiju Jacob, Director and Global Head of MRO Practice, and Manuel Fernandes, Digital Subject Matter Expert & Senior Consultant, MRO Practice, Hexaware Technologies | View article |

| Case Study: Making everything work better | John Hancock, Editor, Aircraft IT | View article |

| Case Study: Controlling Aircraft Tooling using RFID Technology | Jakob Heegaard, Director IT, Jet Time | View article |

| Case Study: Innovations in Aircraft Maintenance at easyJet | Gareth Thomas, Application Manager, easyJet | View article |

| Case Study: Using an M&E IT solution to manage CAMO operations | Yuliya Kornyeva, Senior Project Manager, FL Technics | View article |

Case Study: Controlling Aircraft Tooling using RFID Technology

Author: Jakob Heegaard, Director IT, Jet Time

SubscribeControlling Aircraft Tooling using RFID Technology

When safety considerations demanded a change, it was sensible says Jakob Heegaard, Director IT at Jet Time, to leverage maximum business value from the project

JET TIME

Founded in 2006, Jet Time is an IT charter, business to business (B2B) airline. The business has enjoyed rapid growth since launch. At the same time, the range of activities has also grown from the original IT Charter to include Ad Hoc Charter, ACMI (Aircraft, Crew, Maintenance and Insurance) charter and cargo. By 2008, growth had been sufficient for Jet Time to establish its own maintenance organization, the subject of this case study. The fleet has also grown and, as of 2015, Jet Time operated 28 aircraft – 5 Boeing B737-300, 6 B737-700, 4 B737-400SF and 13 ATR72.

Right from when the in-house MRO was established, we selected OASES from Commsoft as the MRO/M&E IT solution and it has been running successfully ever since. Jet Time’s MRO occupies two hangars and employs about 75 mechanics working a shift pattern and offering 24/7 coverage. We are able to undertake both Line and Heavy maintenance jobs in our own hangars.

MAKING A FULL BUSINESS CASE

Why did we need a new system and process?

The issue that sparked our thinking was to do with safety: our safety management team having identified a problem with the risk of foreign object damage (FOD) in the hangars. We had many findings on this and we had to do something about it. So we sat down to consider what to do and had a discussion to see whether we could combine this ‘must do’ requirement with some other business areas where we could benefit from systems improvements, in order to make a good business case out of the project rather than it just addressing the safety issue. We wanted to be a safer airline but if we could also be a more efficient, more profitable airline: that would be the best outcome.

For instance, when we started to think about this project in the early summer of 2015, as well as the safety issues, we realized we had a manpower utilization problem that had built up as a result of the organizational complexity that had increased along with our rapid growth. So, as part of the overall project, we wanted to create an easier workday for the mechanics who were often complaining about tools not being where they were needed or even of not being able to find the right tools for the job they had been assigned. We wanted to see whether we could combine their needs for better tool management with the other objectives; so, we came up with the idea that we could combine the other changes we wanted with a system to ‘sign-in and sign-out’ of the hangar to better control mechanic locations and to know exactly how many were in a building in order that we could better meet the Danish fire regulations. We call that our ‘come and go’ system.

With tool management, our wish was to be able to make better use of our tools with greater efficiency and utilization as well as being able to track who had used which tool and on what aircraft. The authorities had found poor tool control in our hangars which was a matter that we could not neglect. We had to do something about it in the pursuit of a safety first approach.

THE PLAN

Having determined why we wanted to do this, the next step was to make a plan to combine three systems: OASES, our MRO system; our own manpower planning system (an in-house development) that gives us an overview of all our mechanics, their shifts and their work patterns plus it carries details of Union rules, all to support shift planning in line with production needs which are customer driven and so not regular; and finally the ‘come and go’ solution that we had decided we needed (see above) but had not yet developed. Over and above these challenges, implementation of the new solution needed to be fast to satisfy the authorities and because we wanted to have the new solution in place before the winter of 2015-16.

First draft of plan

The first draft of our plan (figure 1) envisaged that the mechanics would come into the workplace and register their presence using their ID cards which have a chip to identify the individual mechanic. Next step would be to scan the job card; then get the required tools from the Tool Shop using RFID and a reader in a gate and then start working. At the end of the job, the procedure could be reversed, finally, at the end of the work day, signing out. Our plan was to combine the three systems (Manpower, OASES and Tool Management) in a solution to meet all of our needs.

Figure 1

This was the concept that we took to Commsoft, to see how we could use what we already had to achieve our objectives. OASES already included a system for tool control but not with RFID or tool gates but they were happy to work with us in developing a new system so we came together to make a further plan that would add RFID technology to OASES’s tooling control. It also envisaged a simple ‘sign-in and sign-out’ interface for our ‘come and go’ using finger print ID.

As well as the technical plan, we needed commitment from all partners involved, a small task force drawn from mechanics, engineers and business partners and a small project team; plus we had to move rapidly on all of these components.

DEVELOPING THE NEW AND ENHANCED SOLUTION

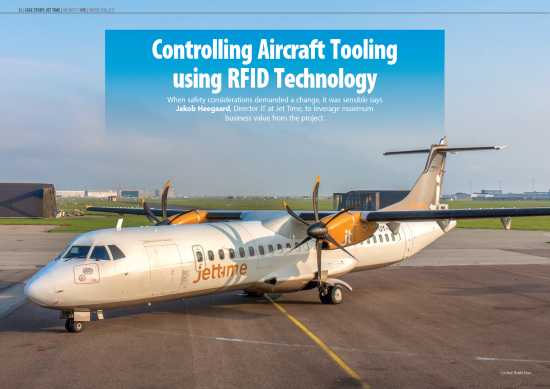

The tasks of preparing each part of the package that we wanted were undertaken in parallel. Commsoft went back to start building the additional capabilities that we wanted with OASES and Jet Time started in our own IT department building our parts, the ‘come and go’ solution for which we decided to use fingerprints rather than punch cards – the system stores all the prints (eight fingers, two thumbs) of each user to make it as easy as possible to sign in or out. The system is also linked with the manpower planning system (see more below) to see whether the mechanic is scheduled to be in work at that time or, indeed, to be leaving at that time. There are usually good reasons for being outside of the schedule but this ensures that those reasons are on record. Figure 2 shows the three main screens including a choice of reasons for when a user is out of their scheduled time.

Figure 2

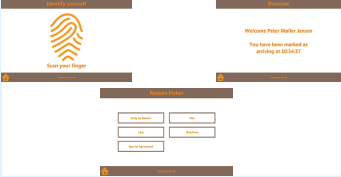

Our next task was to develop the tool gate itself. We visited a number of airlines to see whether anyone already had a similar solution in operation and then put together a team with Commsoft to build the gates. That was not particularly expensive but it took some time to get them correctly adjusted, calibrated and ready to use. The gate consists of two antennae with a pressure plate where the mechanic stands plus there is a monitor. This very brief video…

… shows a mechanic who has come out of the tool store after picking up tools.

And finally we combined the gate with the tool solution to allow us to check where another mechanic had picked up a tool in the shop rather than checking it out from the tool store or where, say, a tool was not properly calibrated. Some of the screens that we devised for the monitor can be seen in figure 3.

Figure 3

When the mechanic walks through the gate with his ID card and a tool or tool bag, the system is able to confirm that it’s the right tool for the job.

Finally, we combined it with the manpower planning solution where we plan all the work for the mechanics (figure 4).

Figure 4

On the upper left of figure 4 is the mechanics’ work plan where the shift patterns for the three shifts are entered. On the right is the screen for the ‘come and go’ package where we can see when mechanics sign-in and sign-out and how those times compare to what was scheduled – early, late or as planned? On the lower screen is a print-out of who is in the building for fire safety purposes and that is also available on mobile so we can always tell the fire department how many people are in the hangars and who they are.

THE IMPLEMENTATION

We originally made a plan that we thought we could deliver quickly – before Christmas 2015. In the event, that had to be revised to January and we finally completed the implementation in February of 2016 as there was a slight set-back in the ‘come and go’ system (see below).

CONCLUSION

We were pleased to say that we had good planning for the project and remembered to get safety management involvement from the outset through close cooperation with our safety management team who came and thoroughly tested the new and upgraded solutions plus asked us all of those questions that we hadn’t thought of ourselves. We found it was important to get the commitment of the whole team behind the project; the mechanics were largely positive but there was a set-back in the ‘come and go’ system with some parts of the unions not at first thinking it was a good idea to track when mechanics sign-in and sign out: we had cleared that with the union leadership beforehand but there was a small delay while that was addressed. Our solution was for all of the management and the technical department as well as the mechanics having to use the fingerprint scanners to sign-in and ‘sign-out.

The tool gates have worked well from February and the mechanics are happy to use them because it’s making their work day easier plus we have achieved greater safety knowing who has which tools and where they will be, i.e. what job. In fact a great benefit from this project was that it was able to combine both safety and cost saving with efficiency optimization. It also improved our management of who was in, who was out in the workforce and why. That is very useful because, in Denmark, you get money from the state for sickness, vacations, leave and the like but we had previously no register of that for our workforce.

So, the original business case was easy because we had to do something about safety but we now also get compensated by the state when employees take a vacation or have sick leave. We regard this achievement of our original requirements plus the additional benefits that we have leveraged from the project as making the whole thing very worthwhile.

Contributor’s Details

Jakob Heegaard

Jakob HeegaardJakob has held various roles in Jet Time since 2008. From an IT consultant working with Jet Time from 2006, Jakob was recruited as IT Manager in 2008, responsible for all Jet Time IT infrastructure and leading the IT department. Since 2015, he has been Director IT. Jakob specializes in IT Systems, Business and IT Infrastructure, Organisation Development, IT strategies and gained his MSc Air Transport Management at City University London in 2014

Jet Time

Jet TimeJet Time operates purely business-to-business air transport solutions for charter and freight companies and others. Since start-up, the business has expanded to include Cargo transport and ACMI; both business areas that make up an increasing proportion of Jet Time’s production. From a small company in 2006 with two aircraft and a handful of employees, Jet Time has become the largest Danish-owned airline with more than 700 employees. The fleet has grown to an average of 30 – Boeing 737 and ATR72.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.