Articles

| Name | Author | |

|---|---|---|

| ProJet Case Study: Getting it right with EFB | Michael Weber, CEO & ACM, Pro Jet Europe, and Michael Rosenkranz, CEO, aircore_systems | View article |

| Column: The World according to IT and me… Assault and Battery | Paul Saunders, Solution Manager, Flatirons Solutions | View article |

| DAT Case Study: iPad or Windows EFB? Or Both | Lasse Nyberg, EFB Administrator, Danish Air Transport (DAT) | View article |

| airBaltic Case Study: AMBER, a more efficient approach | Captain Pauls Calitis, Senior Vice President Flight Operations, Air Baltic Corporation | View article |

ProJet Case Study: Getting it right with EFB

Author: Michael Weber, CEO & ACM, Pro Jet Europe, and Michael Rosenkranz, CEO, aircore_systems

SubscribeGetting it right with EFB

Michael Weber, CEO & ACM at Pro Jet Europe and Michael Rosenkranz, CEO of aircore_systems chart Pro Jet’s move into EFB using a system that well suited their particular requirements

Pro Jet GmbH

Pro Jet is a German operator holding an EASA (European Aviation Safety Agency) AOC (air operator’s certificate) for large aircraft, and operating world-wide. The business, which is divided into several departments, also works under the Bermuda and Isle of Man authorities’ certifications with major aircraft types operated including Bombardier, Dassault and Gulfstream.

Headquarters are in Zweibrücken near Frankfurt. Flight planning certifications for all Pro Jet’s aircraft are held there plus there are some CAMO (continuous airworthiness management organization) duties operated from Berne in Switzerland. Accounting functions are based in Bremen and there is a branch office in Moscow from where the aircraft usually fly. Also in Moscow, there is a flight planning department (covering permits for Africa, Asia and Russia) and a line maintenance station for all three certifications held – EASA, Bermuda and Isle of Man. Normally the business flies world-wide but is not a scheduled operator; conducting ad hoc charters and operating aircraft for their owners.

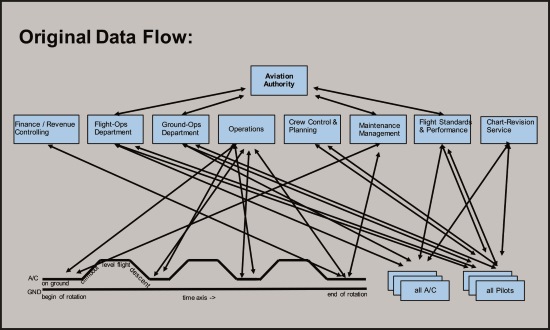

Original data flow

Pro Jet’s original situation with regards to data and information flow was probably where everybody has come from… it was complicated but included the operational workflows that an operator has to have; the pattern will be familiar to readers.

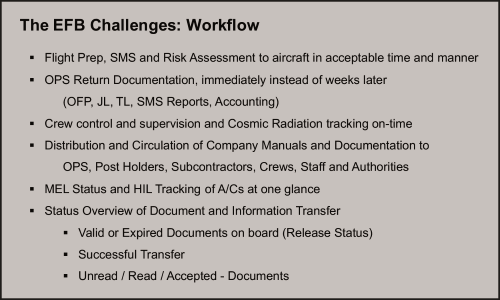

The EFB challenges

Pro Jet wanted to take the next steps; to expand and to make use of the new digital technology now available. But, regardless of what system is used, some things always have to happen. Ops returns have to be filled and comments completed as a requirement of the certifications; all the company manuals have to be distributed, and there has to be MEL ((minimum equipment list) and HIL (hold item list) tracking, which is very important for the airworthiness of the aircraft, even operating as Pro Jet does; also, it is very important to know which crew member has what status of documentation so that, from the overview of documentation, the operator can see the ‘to read’, ‘accepted’ or ‘unread’ status of each document in respect of all staff members, not only pilots.

This can also be done at the technical base because, with headquarters in Germany and a flight base in Moscow Pro Jet does not designate particular stations for specific tasks. Where the aircraft fly, the operator has to do what has to be done; but most flights are just once to one place where they might never visit again and that constitutes a significant challenge.

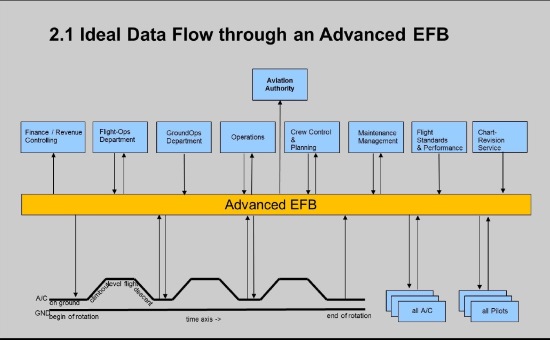

Ideal data flow

An ideal data flow through an advanced EFB should look something like the diagram below…

… and that, in a nutshell, was the goal that Pro Jet had to reach, optimizing airline data workflows to ensure streamlined data and information management and streamlined communication and costs.

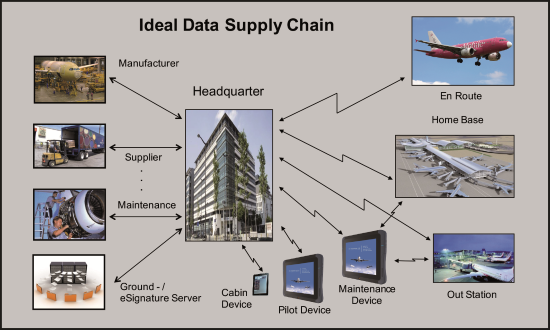

The following diagram below illustrates an ideal data supply chain.

On the left of the diagram are several sources from which data originates, for example the databases of the manufacturers, the suppliers’ parameters with products, prices, bundles, etc., maintenance data from PEM (periodic engineering maintenance) including the aircraft status and history via the electronic HIL and the electronic MELs. Ground Ops applications source their data from service suppliers such as weather services and flight information (including authorities like Euro Control or aircraft positioning data). The signature server is also a basic core system in this data supply chain. In the middle of the figure it can be seen that these data are being worked with and enriched in the Ground Ops environment.

The optimum information transfer to the EFB system is achieved when most record sets are correlated with each other and checked for plausibility. This enrichment process will include the transfer of properties including the data priorities, details of which will be covered later. The first destination for records on this inbound track would be the cockpit, the cabin or the aircraft interface device and the final destination of those records would be Headquarters or, even further back to original sources such as manufacturers, suppliers or maintenance.

Depending on the aircraft mobile and radio communications equipment, transfer of records should be optimized according to the records’ priorities or urgency and transfer efficiency via typical transfer modes such as Satellite, ACARS, 3G and 4G and WiFi. Manual transfers via Bluetooth or a USB stick should be reserved for emergency purposes only; when no radio communication is available.

Concept and realization

The next step for Pro Jet was to take the concept to realization through a series of steps.

1. Requirement definition;

2. Data flow definitions;

3. Software components;

4. Cockpit architecture;

5. Front end architecture;

6. A test run in the system integration lab;

7. A real-time technical status and update overview.

The consideration then was the requirements that are needed in order to be compliant in a modern aviation world. In the first place there has to be a library where everything that is wanted, that has to be held, or that staff need for information, is stored. In the library there should be offline and online availability. Offline is available in the aircraft on the EFB devices so that crew members don’t need to have any connection in order to read every document on the iPad. Online can be used away from the aircraft, to read documents at home, say, and be aware of the latest status with access to the same technology, such as notification of ‘accepting’ and ‘viewing’ documentation.

The journey log records the day-to-day documentation, what was done with the aircraft and consists mainly of the ‘briefing package’, the ‘mass and balance’ and the performance of the aircraft. Importantly from the journey log, the eOFP (eOperational Flight Plan) and the eTechLog must each have a signature to be accepted by the authorities. The eOFP normally documents what was done in-flight: mainly in-flight checks that have to be fulfilled and documented. Finally, the eTechLog records what happened during the flight with regards to the aircraft’s technical status and how can the aircraft be used on the next flight, i.e. is there any restriction. On the eTechLog it’s the HIL and the MEL records discrepancy logs that are needed for a clear handover and, again, everything must be signed according to the regulatory authority rules.

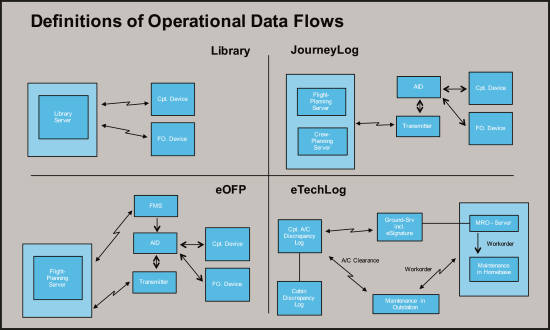

For the next stage, it was necessary to evaluate the essential data flows in this project: documentation transfers from the library; the journey log folder with the crew briefing and flight preparation parameters; the operational flight plan and the technical log book. The figure below shows the basic relationships but the final flow plan that we used was much more detailed.

Although it might not be the most important consideration for pilots, everything that is done to support an EFB costs money so this system is not only for the pilots but also serves the back office. With the aircore_systems system chosen by Pro Jet, everything that happens on the aircraft during its daily operations will generate an invoice or a cost flow; when something is done on board, it always generates a commercial process in the back office for everybody who needs to know what it costs… the cost control components are already there.

Software components

As far as the software is concerned, it is useful to differentiate between operational software applications, data management software and the interfaces to connect all of the applications.

Operational software applications

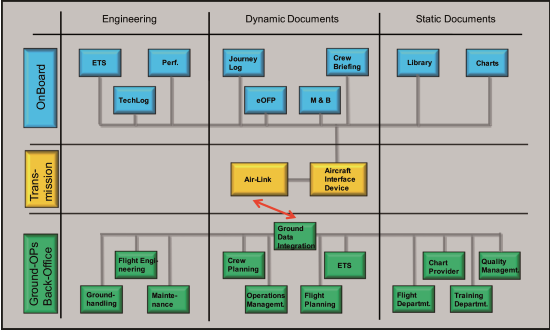

These include ground ops, transmission and on-board elements (see first column of matrix below) that can be further differentiated between engineering, dynamic documents and static documents. The matrix illustrates not only the components in an operational software environment but also where they are placed in that environment and how they relate to each other… how information flows through the system.

Data management

While Pro Jet is a smaller business, it shares with every major operator the requirement to fulfil several certifications: an EASA AOC granted by the German authorities, Bermuda approval granted by the Bermuda authorities and to operate aircraft under Isle of Man regulations. These several certifications can be put into the aircore_systems EFB system so that it always displays, to the person using the system, the correct document for the relevant certification covering the right fleet and the appropriate aircraft.

Journey log

A journey log is largely a day-to-day document: so one journey log documents all the operational data from performance to de-icing to fuel load and other factors; it also contains the briefing package with all the data for flight planning and all the documents that the crew have to have on board and check before take-off.

In the eTechLog module, the configuration for Pro Jet included an electronic hold item list with the aircraft status, the discrepancy logs from the cockpit and the cabin, and in the MEL (minimum equipment list) as well as the FMS (flight management system) failure list. The eSignature module is an authority certified level 3 assignment.

Across the EU, to be legally binding, paperless documents require a level 3 eSignature for which the requirements are…

• The original file must be frozen and unchangeable (e.g. eTechlog report in pdf format);

• A check-sum tool must show that the file didn’t change;

• There must be an EU-wide unique identification number of the signing person, e.g. via chip cards, issued by national authorities.

Fingerprints, PIN codes and on-screen signing with a stylus to produce a graphic image of the signature do not qualify as EU level 3 eSignatures

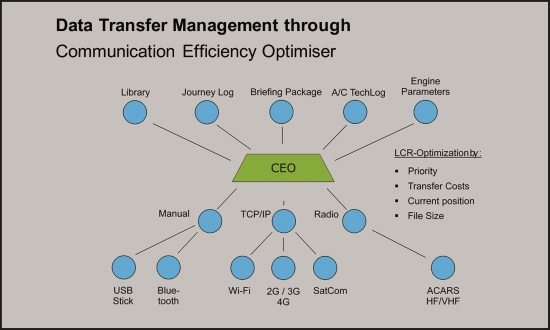

Data transfer management software

The biggest challenges for this component group are high data transfer costs with the need to cater for different countries and varying network suppliers with very different transfer protocols and capabilities. It is also necessary to take into account the different workflows for each fleet and different onboard devices. In addition to these requirements, it is important to ensure that data transfer is minimized, in terms of data types and quantities, without any information loss and with all necessary information transmitted ‘just in time’.

When determining the basic requirements for data management software, the first thing to figure out was all the criteria that influenced optimization of the result, then group them into dimensional blocks and determine how those blocks influenced each other. We started by identifying four dimensions of criteria…

1. Priority, criticality, urgency.

2. Increasing of criticality by time.

3. Aircraft position in the air / on the ground.

4. Aircraft position depending on area (continent or country).

With just these four dimensions, the requirements for data management were already quite complex but then we had to take account of a further six dimensions

5. Character of the EFB device:

a. Fixed mounted;

b. Personal mobile device.

6. Available media… Wi-Fi, 2.., 3.., 4G, Satellite, ACARS.

7. Technical restrictions:

a. Bandwidth;

b. Area coverages;

c. Availability.

8. Channeling and bundling of data packages.

9. Data- and information-workflow control.

10. Price components of network suppliers.

The diagram below illustrates the role of the communication efficiency optimizer (CEO) with its decision algorithms in managing the relationships between the various data packages and transmission media.

Of course, pilots won’t always be worried about the above criteria, they’ll just wish to get on with their job which the aircore_systems system allows them to do. The CEO in the background decides which data is sent and how; so that the pilot needn’t worry about data transfer costs but can rely on the system to make the right decision.

Pro Jet defined data suppliers into outer and inner circles. The outer circle of sources included the manufacturers, suppliers, maintenance (mainly maintenance tracking), flight planning (with Air Support and APG – Aircraft Performance Group) and crew planning. All of these have to be combined into the system. The inner circle represents what is done inside the business with the data; so, from the cockpit and the cabin devices into the aircraft, into headquarters to create on-time documentation for what is happening outside.

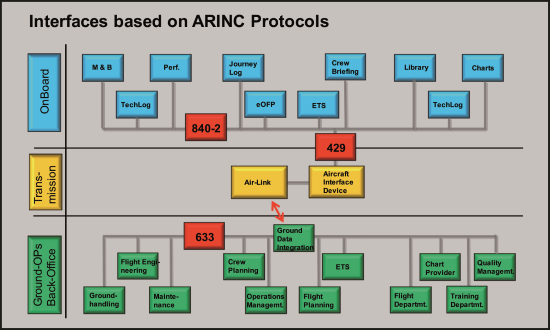

The matrix below groups the interfaces based on ARINC protocols. To set up all the necessary interfaces for the entire EFB environment, Pro Jet and aircore_systems had to decide the syntax on which the interfaces should be based. Either written in a proprietary syntax or based on ARINC protocols – the red boxes on the matrix. Due to the data used coming from several different sources, the decision was to go both ways with ARINC based interfaces as well as individual data handshakes.

Hardware and devices

The next decision was whether to use individual stand-alone devices, on each side of the cockpit and individually linked to the company, or have the devices linked to the company through a common onboard router. In a fully equipped EFB cockpit, the EFB tablets don’t talk autonomously with the back office; their communications are routed through an onboard device. The system controls all onboard and off-board communications and buffers information via a lean transfer and memory device and, where necessary, it allows for tablet cloning. A chip card reader facilitates signature functionality for data record entries that conform to the authority requirements such as those for the eTechLog, the journey log and the eOFP.

The final decision concerned the front end architecture; whether to make it iPad or Windows Pad. The advantages of competing platforms, Apple iOS or Microsoft Windows, had to be balanced against their particular disadvantages. For instance, advantages for iOS included high security standard, excellent for mobile and personal use and iPad spares are available everywhere, on all continents. For Windows, advantages included direct interchange via ARINC 840-2 between all Apps, flexible and fast adjustment to new and potential future environments, and long-term hardware availability. Pro Jet finally settled on iPads because of spare parts availability.

And, of course, Pro Jet worked within valid certifications; the operator didn’t use ‘trial and error’ but worked with aircore_systems on the integration described above. All the systems were tested before implementation and the authorities were invited to see how the new system had been integrated. Only after all that had been completed was it released for use on the aircraft.

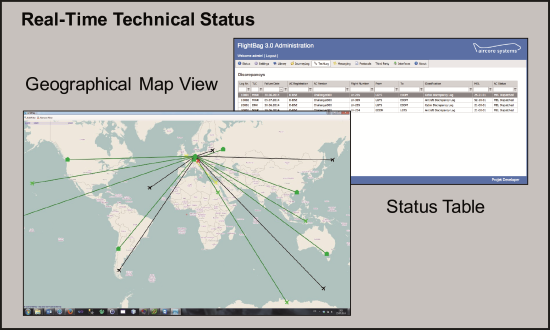

Real-time technical status (see diagram below) refers to all technical system elements; for example, on aircraft tablets and data lines to the outstations. It is of critical importance to the system’s operation that the data update status as well as the technical status is continuously monitored. A cascading display ensures a quick overview. The map displays connectivity to all aircraft and outstations.

Conclusions

Why did Pro Jet decide to use aircore_systems EFB in the operational structure? First it was the communications efficiency; a lot of data are produced during a flight and a lot of data will have been produced before the operator even got all of its certifications; so Pro Jet doesn’t need to think about all of the data payload anymore because the CEO handles it based on priority, transfer costs, current position and file size; the system also chooses the right way to transmit data to headquarters or to all the departments that need to know what has been done with and around the aircraft. The next consideration was the quality of components in the aircore_systems system…

• Workflow management based on the structure of an operator;

• Internal and external data interfacing;

• Increased efficiency;

• Improved transparency;

• Data channeling;

• Time scheduling;

• Least cost routing;

• Prioritization is built into the system…

• Data bundling and…

• Most important for all authorities, there is a good working reporting system into the EFB.

And, with this system, the more you use it, the more efficient it is; use it more, save more money. This is what Pro Jet has experienced using the system in its operation so far.

Contributor’s Details

Michael Weber, Accountable Manager – CEO, ProJet Europe

Michael Weber has been CEO and Accountable Manager for Pro Jet GmbH since January 2013. Prior to this, he was Head of Quality Systems, Safety Pilot and Head of Safety Management at PrivateJet International and, before that, an Independent Consultant in aviation. Havingl graduated in ‘Aviation Systems Technique and Management’, Michael is Assistant Professor at the University of Applied Sciences in Ostfalia, Braunschweig/Wolfenbüttel. He holds an Aviation Transport Pilot License on various aircraft types.

Michael Weber has been CEO and Accountable Manager for Pro Jet GmbH since January 2013. Prior to this, he was Head of Quality Systems, Safety Pilot and Head of Safety Management at PrivateJet International and, before that, an Independent Consultant in aviation. Havingl graduated in ‘Aviation Systems Technique and Management’, Michael is Assistant Professor at the University of Applied Sciences in Ostfalia, Braunschweig/Wolfenbüttel. He holds an Aviation Transport Pilot License on various aircraft types.

ProJet

ProJet operates commercial flights for private and for corporate clients. The company also focuses on servicing and aircraft management for its clients. Each aircraft owner understands the cost of aircraft purchase and ownership but, with ProJet’s staff’s business and commercial aviation management skills, these costs can be optimized, systematized, and substantially reduced using a professional approach to aircraft management and operations.

Michael Rosenkranz, Managing Director, aircore_systems GmbH

Michael Rosenkranz is founder and CEO of aircore_systems, an EFB and eEnablement solution provider. He holds degrees in ‘Engineering’ and ‘Economics & Technology’. Since 1990 Michael worked in IT consulting for process optimisation and branch communications and, in 1992, founded the PAS-Group. In 2007 the subsidiary aircore_systems was founded. The philosophy behind aircore_systems’ solutions is that aircraft are data-rich components of an airline’s IT infrastructure that should be continuously connected with and embedded into all airline data processes.

Michael Rosenkranz is founder and CEO of aircore_systems, an EFB and eEnablement solution provider. He holds degrees in ‘Engineering’ and ‘Economics & Technology’. Since 1990 Michael worked in IT consulting for process optimisation and branch communications and, in 1992, founded the PAS-Group. In 2007 the subsidiary aircore_systems was founded. The philosophy behind aircore_systems’ solutions is that aircraft are data-rich components of an airline’s IT infrastructure that should be continuously connected with and embedded into all airline data processes.

aircore_systems

aircore_systems GmbH is a part of the PAS-IT-Group. The company has branches in Bremen and in Munich. The business designs and provides software solutions and consulting for the airline industry leveraging a combination of IT knowledge on the one hand and airline knowledge on the other. Several staff members hold a valid captains rating on transport category aircraft in addition to their academic degrees.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.