Articles

| Name | Author | |

|---|---|---|

| ProJet Case Study: Getting it right with EFB | Michael Weber, CEO & ACM, Pro Jet Europe, and Michael Rosenkranz, CEO, aircore_systems | View article |

| Column: The World according to IT and me… Assault and Battery | Paul Saunders, Solution Manager, Flatirons Solutions | View article |

| DAT Case Study: iPad or Windows EFB? Or Both | Lasse Nyberg, EFB Administrator, Danish Air Transport (DAT) | View article |

| airBaltic Case Study: AMBER, a more efficient approach | Captain Pauls Calitis, Senior Vice President Flight Operations, Air Baltic Corporation | View article |

airBaltic Case Study: AMBER, a more efficient approach

Author: Captain Pauls Calitis, Senior Vice President Flight Operations, Air Baltic Corporation

SubscribeAMBER, a more efficient approach

A project to leverage the wider value of RNP, explains Captain Pauls Calitis, Senior Vice President Flight Operations, Air Baltic Corporation, has delivered all the anticipated benefits and more

Air Baltic

Before moving to the main subject of this case study, I should set the scene with a brief profile of Air Baltic. The airline is based in Riga, Latvia and operates to more than sixty destinations around Europe and the Middle East, completing some 45,000 flights and carrying three million passengers annually. Air Baltic has extensive codeshares with most of the large legacy carriers in Europe and operates a fleet of 28 aircraft divided more or less equally between the Bombardier Q400 new generation turboprop and Boeing 737.

A new idea to use an established resource

There is a great deal written in this and other publications about some of the excellent new pieces of equipment on the aircraft and on the ground whose purpose is to improve the operational effectiveness and efficiency of aircraft. However, this article is about using a piece of equipment that is already on board most modern aircraft and what can be achieved without having to add or do anything new on the aircraft. The subject of this case study is more about changing a mind-set; using a familiar piece of equipment in a new way to gain efficiency.

At Air Baltic, we have called this process The AMBER (Arrival Modernization for Better Efficiency in Riga) project. Amber is a pine resin based material which can be found in our area and which is formed over a very long time but offers some worthwhile properties. Hence the acronym AMBER was coined to describe our project which, while it took a while to complete, has generated worthwhile performance properties. The start, three years ago, was when we had a familiarization visit in Riga from Airbus Pro Sky. At that meeting, the idea was generated that we should undertake a project in Riga to implement RNP Arrival. Briefly, RNP (required navigation performance) is a satellite based approach which, instead of using ground-based navigational equipment to guide the aircraft down to the runway, uses satellite information that’s already out there available for aircraft to pick up. Much the same as using GPS in our cars, the aircraft can follow a specific route based on guidance and information being received from the satellite. Riga turned out to be an ideal location to implement one of the first RNP approach processes, as we’ll see later.

Working in partnership

Of course, a program like this cannot be managed or implemented in isolation and, for the AMBER project, Air Baltic is a partner with SESAR (Single European Sky ATM Research) who provided the European funding for the project as part of their Joint Undertaking program. Other key partners in this project are Airbus Pro Sky (Airbus’s service provider at the forefront of RNP throughout the world and with considerable experience of the concept and implementation), the Latvian air traffic control service (LGS), the Latvian civil aviation agency (CAA) and Riga International Airport.

Why RNP for Riga?

Traditionally, the flight control infrastructure in Europe is ground based and established, so this was about moving forward with an idea using this new but already installed technology. But why RNP-AR (RNP – Authorization Required) and why in Riga? Traditionally when we think of RNP, it is something to be deployed in challenging aerodromes where there are obstacles and/or terrain issues. It is often used in aerodromes such as Kathmandu or Innsbruck where a precise satellite signal will allow the pilot to fly a very specific route and will make accessible airfields that might otherwise have limitations in terms of using ground based equipment. Also RNP has been deployed in developing areas like China and other parts of Asia where many new airfields are being built and where, instead of investing in ground based equipment, they are moving directly to RNP. Also RNP has the benefit that, following the satellite trajectories, it is possible to avoid having to have ‘straight-in’ approach segments and to instead model the approach with ‘slalom’ type curves to avoid built-up and noise sensitive areas; a particular issue in Europe where many airports are surrounded by populous communities. These are the usual reasons for adopting RNP.

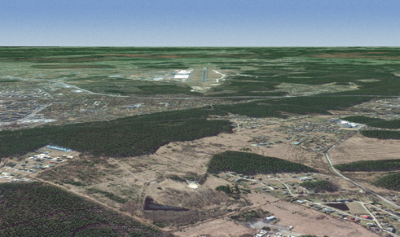

Looking at Air Baltic’s base in Riga, Latvia, it doesn’t seem to pose those challenges usually associated with a decision to use RNP. The area is flat and green as you can see from the photograph of the short final approach.

There are no terrain challenges or obstacles, neither is the airport in a built-up area where noise might be a concern. So readers might wonder why would Air Baltic wish to implement RNP and why would the EU wish to fund such a development as they did? We wanted to use this program to initiate RNP on turboprop aircraft; previous adoption has been for jets (narrow- and wide-bodied) but Air Baltic wanted to demonstrate that it could be effective also on turboprop aircraft to show that scale matters and to show that, even with the inherent efficiency of turboprops, there were still gains to be made. We wanted to minimize track miles by optimizing routing into Riga and to achieve greater efficiency by applying continuous descent. It all has the potential to deliver benefits that any operator would wish to achieve: reduced fuel burn and emissions with minimized track miles and lower noise levels through a more efficient arrival plan.

Approaching Riga… then and now

Arrivals at Riga are from the North towards the South and on a typical day using the runway, arrival air traffic control sequencing follows a pattern that looks like the one on the first map image below.

A typical days arrivals at Riga before RNS was implemented

Readers will see that the approaches have been made using radar vectors with many of the aircraft being taken out into the Baltic Sea and with air traffic control also extending paths downwind in order to get the aircraft in. With RNP, a specific approach track is created following satellite navigation routes; and it can be curved. By combining these two elements, it was proposed to do the following – see second map image below.

The more efficient RNP Arrivals tracks can be clearly seen on this map

The arrivals track was definitely shortened thus achieving the desired track mile reduction objective. We created two different scenarios: the initial one (blue track) was more conservative and still went out over the sea area while we also pushed the possibilities to manage a very tight approach (yellow track) because we wanted to keep the track south of Jūrmala, a city on the coast, to get the most reduction in noise and achieve the shortest possible approach. Once designed, these approach tracks then had to be validated and go through the normal approvals process for procedures design before being ‘flown’ in simulators and tested for both jets and turboprops because, although initial trials were conducted for the Q400, they will be open for all operators to use. Finally, prior to implementation, we had to test fly the new tracks to prove that it could be done in real flying conditions.

How the program was delivered

The time line for our project really started when the funding from SESAR was approved in March 2013 and then, in October of that year, we launched the project with the coordination meetings. It took that winter of 2012-13 to design the procedure and to get it to a testing phase, by May 2013. We were able to start the flight trials in September 2013 and we completed the flight trial program by May of 2014 with 124 flights successfully flown using the RNP arrival tracks and the data from those flights collected. In September 2014, the material was collated into a complete report for SESAR which can be read on the SESAR website.

Improvements achieved

We reviewed the specific results against the broad objectives that we had set for the project (see above) and were very pleased to find there had been improvements in every area we had expected. With an RNP approach, the arrival track was shorter than for a conventional approach by some 13-20 nautical miles; a significant saving which, in turn, generated fuel and emissions savings in the order of 20-30 per cent. We demonstrated that, with this type of arrival, we can and do make a continuous descent managed in such a way that, since such a precise track is being flown, makes for highly predictable aircraft control. Monitoring showed an improvement of the noise footprint on the ground and something that we had not set as an objective, so it was a spin-off benefit, was that for both the crew and air traffic control there was a significant reduction in the number of communications needed during an approach.

Now, returning to the earlier statement that Riga turned out to be an ideal location to implement one of the first RNP approach processes. The reason for this is that Riga is Air Baltic’s only base and there are many airlines that are similar in that respect. So, we reasoned that if we could cover our base airport with an RNP arrival, then we would already be getting 50% or more of our landings (the landings at our base airport) with this more efficient arrival process. We also realized that there is no point in waiting for others to do this first if you can make proportionally large gains right away for an airline with only one or two operating bases.

A management challenge

One challenge was how to manage a program and change such as this with a range of stakeholders, different technologies and an attitude to this type of approach which, in Europe, does not seem very positive. It turned out to be more of a challenge than we had anticipated getting the authorities, air traffic control and other players all moving forward to execute the project. Also, our time line slipped, not because of the technical challenge (the procedure was designed on time) but it was the human element that made it difficult. Fortunately, because Latvia is a small country, we were able to move the process faster than might have been the case for a larger country with a busy airport like Charles de Gaulle in Paris or Heathrow in London. For airports like that, it will be a long time before this type of approach is feasible because it is so difficult to change procedures, establish infrastructure and so on. This is a case where the smaller players can make a difference and implement change in their areas.

Traditionally SESAR money goes to the big projects with big players but it isn’t necessary to always go for the big projects or the most complex ones, even if they might, at first, seem the most enticing. By going with smaller and more manageable projects with smaller players it’s actually possible to get to a situation where lots of small projects mean that the gains can more easily be realized.

Conclusions and lessons learned

When we consider the success factors it is not so much the technology as the human factors which, again, come to the fore. It’s important to get buy-in from everybody involved in and affected by the project and to make that happen it’s necessary to bring together the players involved and explain to them the gains from which they’ll benefit. People don’t like change so it’s all about convincing them and showing them that it’s needed. There needs to be a process driver or somebody moving the project forward: big policy statements about the implementation of strategic goals alone are not enough, there needs to be ‘boots on the ground’, a team that believes in and is actually moving things forward, and who will make the change happen. Don’t make the mistake of believing that something will get done just by saying it will be implemented. And, of course, the key element throughout the program is communication, communication, communication… keep everyone on-board together and informed. For instance, in this project, each week during the test flight phase we circulated a status report explaining how many test arrivals had been flown and what were the initial results: and we sent this to all the players involved to fully engage them into the process.

Having successfully completed this project, we’re already enjoying the gains in Air Baltic and I hope that we have laid the foundations for RNP arrivals to be more widely used with all of the environmental and financial benefits that will generate.

An RNP track test approach

If you’re interested to see the new approach there is a brief video at and, as you’ll see from the closing frames, the approach shown saves an average of 13 nautical miles (24 km) per flight which translates to 70kg less fuel burned, 150 less kg of CO2 and a time saving of three minutes per approach. These figures are averaged from 124 trial flights between November 2013 and May 2014.

If you’re interested to see the new approach there is a brief video at and, as you’ll see from the closing frames, the approach shown saves an average of 13 nautical miles (24 km) per flight which translates to 70kg less fuel burned, 150 less kg of CO2 and a time saving of three minutes per approach. These figures are averaged from 124 trial flights between November 2013 and May 2014.

Contributor’s Details

Pauls Calitis, Senior Vice President Flight Operations, Air Baltic Corporation

Pauls has been in senior management for 15 years, involved in airline operations, with significant experience managing both rapid growth and consolidation. He was an initiator and project leader of AMBER and coordinated the effort between the partners in the project. Pauls is currently licensed to pilot the B737 and B757 and remains actively involved in crew training and an executive board member of the Air Baltic Training Centre. He has completed a Global Aviation MBA.

Pauls has been in senior management for 15 years, involved in airline operations, with significant experience managing both rapid growth and consolidation. He was an initiator and project leader of AMBER and coordinated the effort between the partners in the project. Pauls is currently licensed to pilot the B737 and B757 and remains actively involved in crew training and an executive board member of the Air Baltic Training Centre. He has completed a Global Aviation MBA.

Air Baltic

Air Baltic

Based in Riga, Latvia Air Baltic operates to more than sixty destinations with some 45,000 flights carrying three million passengers annually. The airline has extensive codeshares with most of the large legacy carriers in Europe and operates a fleet of 28 aircraft divided more or less equally between the Bombardier Q400 new generation turboprop and Boeing 737.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.