Articles

| Name | Author | |

|---|---|---|

| Next-Gen Airlines, a Digital Business | Ravinder Pal Singh, Chief Information & Innovation Officer, Vistara | View article |

| Data Transition across the aircraft life-cycle and M&E system implementations | Sander de Bree, CEO, EXSYN Aviation Solutions | View article |

| Case Study: MRO Technology Innovations and Learning from other industries | Franco Caraffi, Marine Systems Director, Costa Corporate I&CT, Costa Crociere S.p.A., and Adrian Schmitt, Data Science Team, Lufthansa Industry Solutions | View article |

| Machine Psychology – don’t stop shouting | Soumitra Miraj, Founder of www. InnovativeBinaries.com, and Michael Parsons, Director Travel and Transport Cloud and Data Management Solutions, Oracle | View article |

Machine Psychology – don’t stop shouting

Author: Soumitra Miraj, Founder of www. InnovativeBinaries.com, and Michael Parsons, Director Travel and Transport Cloud and Data Management Solutions, Oracle

SubscribeMachine Psychology – don’t stop shouting

Soumitra Miraj of InnovativeBinaries and Michael Parsons of Oracle explain how the growing capabilities of artificial intelligence and machine learning can bring value to aircraft maintenance

SEEKING ATTENTION; BUT FOR A PURPOSE

The crying baby, the constant ping of a mobile phone, the raging car alarm; all are noisy irritations that can distract and annoy. In the machine world noise is also seen as a nuisance that confuses and blurs results. However, for those that are attentive and listening, there is often value in these signals. In many cases the machine may be shouting ‘fix me!’ But its request for help is obscured by noise that is generated along with the plea. Much as a psychologist will listen to a patient and examine possible contributory factors such as sleeping and eating patterns, and look for any negative thoughts that might be causing or contributing to a problem; in the world of machine learning (ML) and artificial intelligence (AI) similar techniques are being used to ‘listen’ to the machine, interpret its needs and learn what makes it ‘tick’.

THE STEADY RISE OF AI AND ML

Artificial intelligence and its sub set machine learning have been around for a many years. Arthur L. Samuel was an early pioneer in the field of AI and wrote a paper in the IBM Journal of Research and Development in 1959 titled “Some Studies in Machine Learning Using the Game of Checkers”. In it he uses the phrase “machine learning” and is concerned with “the programming of a digital computer to behave in a way which, if done by human beings or animals, would be described as involving the process of learning.” AI and ML continued to be a focus fueled by interest and excitement in the possibilities of a truly intelligent machine such as Arthur C. Clarkes HAL9000 sentient computer in the movie ‘2001 A Space Odyssey’.

The promise however was hampered by a number of limitations such as the availability of sufficient computing power; Hans Moravec argued in 1976 that artificial intelligence requires computer power in the same way that aircraft require horsepower. Below a certain threshold, it’s impossible, but, as power increases, eventually it could become possible. The inability to work with large data sets was also a hindrance; Ross Quillian’s s work on natural language understanding was demonstrated using a vocabulary of only twenty words because that was all that could fit in memory. Fast forward to the present day and we carry a thousand times more computing power in our back pocket than NASA had at their disposal for the 1969 mission to the moon. This combined with a rapidly changing landscape of technology which offers larger data storage and faster processing for a lower costs opens up a new horizon for the application of machine learning. It is no longer necessary to be as selective on the data we keep, information that previously seem extraneous and not worth the cost of retention can now be used for potential insight.

APPLYING AI AND ML TO MAINTENANCE

In the maintenance domain the application of AI and ML to solve large complex problems has been experimented with for many years in an attempt to develop a more responsive and effective approach to a variety of problems. The ability to identify problems, learn patterns and mitigate the impact of a failure is of particular interest. An analogy has been drawn between an equipment failure and its subsequent impacts and the outbreak of a disease in the human population: both events place an unexpected demand and stress on the systems that support them – the hospital, the maintenance facility or the supply chain.

In the field of public health AI and machine learning is being used to predict disease outbreaks by bringing together data from ecology, biogeography, and public health studies to identify the likely emergence of an outbreak, allowing public health officials to put in place countermeasures. Similarly maintenance managers would benefit from the screening and analysis of health data from the aircraft’s on board sensors, maintenance record histories, operational parameters and equipment performance data to identify and prioritize statistically significant events. The collection and analysis of this data has been an ongoing endeavor for the OEM’s with IVHM (Integrated Vehicle Health Monitoring) systems aiming to capture and process the information. There are often, however, limitations placed on the sub systems’ components that are monitored and whilst it is true that these systems can offer some significant advantages they are often more diagnostic in nature and fail to fully leverage the benefits of applied machine learning across a broader operational data set.

DIFFERENT APPROACHES TO MACHINE LEARNING

Supervised learning

There are a number of machine learning techniques that can be applied to a given data set based upon the problem statement and the type of data available. One approach is supervised learning in which a training data set is used and has a known result. The model makes predictions using this data and produces a ‘reasonable’ inferred output in unseen situations. In psychology this is often referred to as concept learning, in which lists or rules or characteristics are used to allocate an object to a category or class; for example when we think of the concept ‘aircraft’ it includes the rule ‘must be able to fly’ and ‘inanimate’. Through the application of the rules we are able to distinguish it from a bird, for example, and over time, as we develop experience in the application of the rules and classifications, we learn to identify the different types of aircraft based on their characteristics. Supervised learning can be used to determine whether or not a flight will be delayed by leveraging data on flight, carrier, punctuality, origin / destination and weather conditions to predict with a relatively high degree of accuracy whether your mid-afternoon flight from Chicago in November is likely to be delayed.

Unsupervised and semi-supervised learning

The opposite approach to supervised learning is unsupervised learning. In this case the input data is not labeled and we do not know the result. The model attempts to deduce patterns in the input data through the application of the algorithm to organize similar data, identify patterns or reduce redundancy. Semi-supervised is a hybrid of both approaches and deals with a mixture of labeled and unlabeled data.

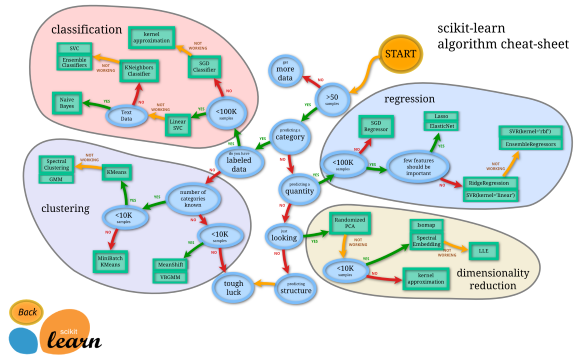

Within each of these paradigms there are several different types of modeling techniques that can be applied and it is important to select one that is appropriate to the type of problem you are trying to solve. In order to achieve good results it is important to combine an understanding of machine learning, the nature of the problem, and the quality, quantity and type of the data with specific domain knowledge and understanding. Often this can be a stumbling block as it requires a variety of skills and capabilities to come together and collaborate on the problem. The flow chart from scikit in figure 1 on choosing the right estimator provides some generalized guidelines in the selection process.

Figure 1

MAINTENANCE APPLICATIONS

Artificial Neural Networks

Over the years many and various machine learning techniques have been applied in the aviation maintenance field, one particular area of interest is anomaly detection where we attempt to identify patterns in data that indicate a deviation from the normal operating profile. We can think of these as a single data point or small cluster of data points that are significantly different from the rest of our data set. These differences lie outside the normal operating profile (NOP) of the asset and are flagged as anomalies. A fundamental requirement of this ‘intelligent’ monitoring agent is not only the detection of the anomaly but also the identification of the contributing component to that abnormality. There has been some interesting research that adopts this traditional approach and attempts to solve the problem through the application of Artificial Neural Networks (ANN).

ANNs are based on the idea of emulating a biological nervous system such as the human brain and, like people, they learn by example. ANNs have the added advantage of massive parallelism, a distributed representation of knowledge, generalization ability and fault tolerance capabilities. They are commonly used for regression and classification problems and are thought to be one of the more promising techniques for predicting the Remaining Useful Life (RUL). Mazhar et al (2007) examined the potential of combining a Weibull reliability assessment model which utilised degradation and condition monitoring data with an ANN model to estimates the remaining life of used components. More recently Jain et al (2014) have applied the technique to predict the RUL of an aircraft engine which has unknown initial wear. They used the operational parameters altitude, mach number, and throttle resolver angle as well as measurement data from 19 different sensors that provided data on a range of parameters such as temperature at fan inlet, LPC (low pressure compressor), HPC (high pressure compressor), LPT (low pressure turbine), the physical fan speed and the engine pressure ratio to predict the RUL. Another application of ANNs was investigated by Rao et al (2015) who have experimented with ANNs by tracking failure mode effects, control actuators and sensors subsystems using s SAAB’s open source Generic Aerodata Model (GAM) . The results showed that an ANN, once trained was able to identify the anomalies and indicate the root cause of the failure.

Genetic Algorithms

Whilst Neural Networks are currently generating a lot of interest, a more establish technique applied in maintenance, is the Genetic Algorithm (GA). They bear a certain resemblance to ANNs in that they have a biological context but are based on the theory of natural selection and genetics. They mimic nature in as much as they use the process of selection, recombination and mutation to evolve a solution to a given problem. GA’s are an optimization technique that work with large numbers of continuous or discrete variables and are therefore useful when we turn our attention to operational problems such as the optimization of maintenance scheduling. Lapa et al discusses how they could be used to optimize maintenance schedules by considering factors such as the probabilities of requiring repairs and their costs, the typical downtime, costs, maintenance impact on the systems reliability, probability of imperfect maintenance, etc.

OPPORTUNITIES AND WAYS TO LEVERAGE THEM

The sheer variety of available algorithms for machine learning problem solving can seem overwhelming. Genetic algorithms, Bayesian estimation methods, artificial neural networks, perceptrons, random forests, K-nearest neighbor, support vector machines… they are all able to listen to our machines and help us interpret and predict their needs. Although variations exist in the algorithms and some may be more suited than others to a particular problem, what is perhaps equally if not more important is the availability of a scalable and robust environment that allows easy upload, transformation and processing of data. This becomes increasingly critical to a company’s success as it is no longer sufficient to be the best at what you do; you also need to be the best at analyzing what you do as well as interpreting and learning from what you do. GE Chairman and CEO Jeff Immelt remarked at the third ‘Minds + Machines’ summit that, “If you went to bed last night as an industrial company, you’re going to wake up this morning as a software and analytics company.” highlighting the fact that every company needs to focus on extracting value from the data it generates.

Pulling together all the necessary resources, data science skills, domain knowledge as well as the hardware and software to take full advantage of the machine learning potential can be challenging even for the largest players. As a result we are starting to see the emergence of specialized cloud based platforms that provide data hosting and pre built and trained ML algorithms. A ‘Model as a Service’ (MaaS) approach to machine learning makes it easy for companies to start using ML to analyze large data sets allowing them to them to deliver more accurate results faster without the expense and risk of building, deploying and managing the infrastructure internally. They are able to access state of the art machine learning code easily, allowing them to simplify and ‘operationalise’ the use of data. Now perhaps we can truly listen to and understand the machine when it shouts for help!

REFERENCES IN ARTICLE

Mazhar, M.I., Kara,S. and Kaebernick,H. (2007) Remaining life estimation of used components in consumer products: Life cycle data analysis by Weibull and artificial neural networks. Journal of Operations Management, Vol 25, 6, 1184-1193

Pallanti Srinivasa Rao , Sreeram Mohan , and Venkateshwar Chindam – AI Based On-Board Diagnostic and Prognostic Health Management System. ANNUAL CONFERENCE OF THE PROGNOSTICS AND HEALTH MANAGEMENT SOCIETY 2015

Lapa, C.M.F., Cláudio, M. N.A. Pereira,C.M.N.A. and Paes de Barros, M. (2006) A model for preventive maintenance planning by genetic algorithms based in cost and reliability, Reliability Engineering &System Safety, Vol.91, 2, 233-240

Amit Kumar Jai, Pradeep Kundu, Bhupesh Kumar Lad – Prediction of Remaining Useful Life of an Aircraft Engine under Unknown Initial Wear, 5th International & 26 th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) December 12th–14th, 2014,

Contributor’s Details

Michael Parsons

Michael has over 17 years of experience in the aviation industry with a focus on complex asset management and analysis. He has led diverse, multi-cultural teams on large, complex engagements globally, and specializes in the design and deployment of enterprise application and analytically solutions. He is the Director Travel and Transport Cloud and Data Management Solutions at Oracle.

Soumitra Miraj

Soumitra has a background in computing, an FAA commercial pilot’s license, and qualifications in strategic management from Harvard University. He has over ten years of experience in aircraft maintenance & engineering and MRO applications and is the Founder of Innovative Binaries.

Innovative Binaries

Innovative Binaries provides an artificial intelligence platform for operators to quickly leverage benefits of their aircraft sensor data. Among other services the platform provides predictive maintenance, inventory optimization, and fuel optimization in a unique and holistic manner and is in line with the connected aircraft initiative. Users of the platform include aircraft operators, MROs, aircraft and component OEMs, and commercial drone operators. Innovative Binaries has recently been selected by Airbus for its BizLabs program.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.