Articles

| Name | Author | |

|---|---|---|

| Case Study: American Airlines addresses repetitive faults with data | Karl Ries, Senior Manager Tech Support Desk Maintenance Ops Control, American Airlines | View article |

| Industry Standards: an ATA perspective | Ken Jones, Director Electronic Data Standards, ATA e-Business Program | View article |

| Case Study: Alaska Airlines takes control of inventory | Jim Parish, General Manager Material Stores and Distribution, Alaska Airlines | View article |

Case Study: Alaska Airlines takes control of inventory

Author: Jim Parish, General Manager Material Stores and Distribution, Alaska Airlines

SubscribeAlaska Airlines takes control of inventory

Jim Parish, General Manager Material, Stores, and Distribution, Alaska Airlines explains their experience developing a RFID system for Inventory Management

We have been working to get RFID into our inventory system for Alaska Airlines since early 2017. There are some internal IT challenges around network security and we’re working through those. Overall, we’re very close to a successful test of the technology and the TRAX software changes necessary for us to enter a Proof of Concept trial at Phoenix Sky Harbour Airport.

THE PROBLEM AND THE PROTOTYPE

Currently, Alaska Airlines has parts storage facilities from Anchorage, Alaska all the way down to San Diego. Many of our Maintenance sites such as San Diego , Phoenix, or San Jose, Calif. do not have 24/7 coverage with stores personnel. For many years we have operated under a manual system where the technician is responsible for writing down the material that was used so we could keep track of what materials are issued out. As with any manual system, we are very dependent on the technicians accurately documenting their parts usage so we can resupply effectively and avoid any NIS situations at individual stations.

When we wanted to determine whether this RFID system would work, we decided to designate a prototype warehouse operation in Phoenix where aircraft are usually kept overnight. The weather in Phoenix is good enough to let us undertake maintenance that can’t always be conducted outside in, say, Seattle or Portland, Ore. where it sometimes rains. Because of this, Alaska Airlines maintenance planners schedule aircraft to Phoenix knowing we don’t have hangar space but can still carry out lubes, cabin interior checks and the like. We hold approximately $30,000 worth of inventory in a fairly small storeroom in Phoenix. That material is put there for night mechanics to come in and take what they need. As mentioned above, they are supposed to write down on a chart exactly what they have taken. The reality is that people get busy, get overcome by events and are in a hurry; so the accuracy of this human led inventory system isn’t always as complete as it should be.

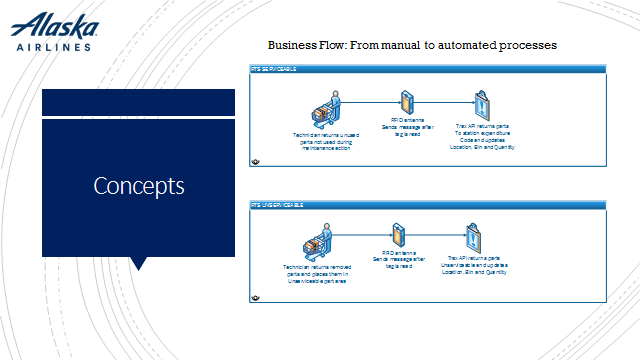

Figure 1

In short (figure 1), inventories at unmanned stations are inaccurate and changes are not visible in our database so it requires people to go out and check.

THE OBJECTIVE – HOW IT WILL WORK

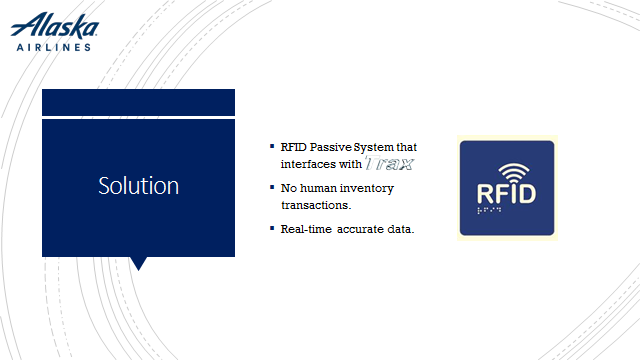

For inventory management and moving to an RFID (Radio Frequency Identification Device) we would consider it a home run if all parts in a storeroom were identified with passive RFID tags so when the mechanic needs a part, he or she can take the part and go through a door where, as soon as they exit, a debit is registered on the inventory through an RFID antenna array and through Amazon Web Services, feeding back to our servers in Seattle to update TRAX in real time. Conversely, the system would credit the inventory of an item once the RFID tag is scanned by the antenna. This is a summary of what we are trying to accomplish with this project.

Figure 2

The current system is passive (figure 2) and one of the challenges we are trying to overcome is that we would like to utilize our current RFID system, which we use for scanning employee ID badges, to allow us to tie the material that was taken to the mechanic who took it and the time. We’re not quite there yet because of differences in frequencies; the RFID system works on a higher frequency than standard RFID reader badges which operate at a cell phone range of around 980 megahertz. There are a couple of additional challenges that we need to work through but we are hopeful that eventually, when a mechanic takes a part, not only will we know the part has left the storeroom; we will also know who took it making it possible to backtrack and see who actually worked on the aircraft and what material was used. Ideally, we would be able to know what MEL (Minimum Equipment List) the mechanic was working on, the work order number, the parts that they use, the time stamp, and other information. We expect to get there eventually, but we’re taking it one step at a time.

THE OBJECTIVE – WHAT IT WILL DO

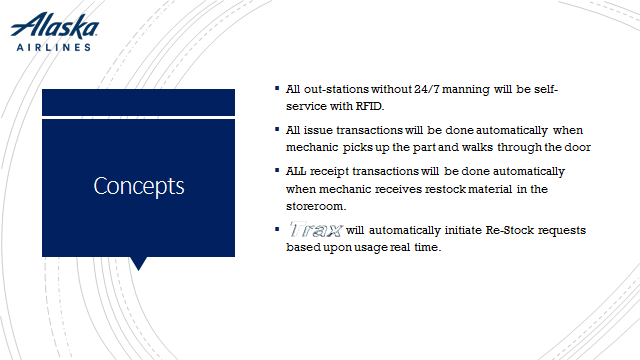

Our goal at Alaska would be to equip all of our outstation maintenance activities with an RFID system. By ‘outstation’ we mean a facility where material comes in and out, and is used frequently, but there are not enough stores personnel to provide 24/7 coverage for issuing out material. With our current manual system, we don’t know if or when material was used unless we are told by the mechanics or we perform a Wall-to-Wall Inventory. With the RFID system (figure 3), people won’t need to write down what they take from stores because the antenna used to arm the door (single entry/single exit) will pick up the RFID tag as it passes by the antenna array. Challenges include having too many parts too close together so that the tags don’t read accurately. We’ve put ground rules in place to deal with that and, as long as the rules are followed when the tag is being put on the material; mechanics only take four or five items at a time and they make sure that they’re not stacking items on top of each other, the process works very well – we get near 100 percent on everything.

There are cases, when dealing with metal parts, where we may choose to use an ‘insulator’ or buffer tag – a thin sticker that goes under the actual RFID tag – to help insulate the signal from the metal underneath the part to the antenna that is in the tag itself. This will help ensure an accurate read as opposed to confusing the system with all the metal on the part in the bag.

Figure 3

Our current mode of operation is that people write down what they need, and then once a week or so, we find out in Seattle what was used for that activity. We then pull from Seattle stores and send to Phoenix to re-supply them. Under the RFID system and using TRAX, the second that the person removes the part from stores, it will send a signal to TRAX, debiting the inventory. We also use a program called Zealous that assists Alaska’s in inventory management and demand forecasting. It automatically analyses the data and, depending on the allocation and the safety stock level, either sends a signal to Seattle to pick another part to replace it or does nothing because the inventory level is above the safety stock. There are a lot of moving parts but the system is automated and works well when used within our business rules.

RFID PROS AND CONS

There are pros and cons with RFID (figure 4) which I’ve set out below in a bullet list.

Pros

- Does not require line of sight for scanning.

- Can reduce labor costs.

- Improves visibility of inventory with real-time updates: The primary goal is to have an accurate inventory and to be able to resupply and know what has been used at maintenance outstations the night before, so we can send that material on the next available flight.

- Tracking of returnable containers or pallets.

- RFID tags hold more data: The data that we’re putting in right now emulates the data that is on our barcode tags (part number, nomenclature, bin, location…) with the difference under the RFID system that all that information is encoded electronically into the RFID tag so that it is picked up by the antenna and sent through the system.

- No damage or loss of labels.

Cons

- Cost of RFID tags: This was one of those things that initially was going to be the biggest constraint. The concern was, ‘Can we afford RFID tags on 30,000 line items if the RFID tags cost 50 cents each?’ It was a good business case question but we focused on ‘this is what Alaska needs’ as opposed to ‘here’s what the industry does as a norm’. As for the cost of working with the standard 4 inch x 2 inch tag and modifying our label, we were able to get the cost down well below 50 cents to around 20 cents with the possibility of going lower due to economies of scale and purchase guarantees for suppliers.

- Radio interference problems: We have mitigated a lot of these by utilizing buffer tags (see above) that go under the actual tag. Another thing that helps with this issue is ensuring mechanics know how the antenna works, what we want them to do, and to make sure the item is scanned. In our Phoenix prototype, there is a light bar that gives a visual green light and the mechanic can hear an audible ‘BEEP’ whenever a tag passes through the antenna array. This indicates the RFID system successfully scanned the tag as they walked out of the storeroom, which helps assure the mechanics that the system is working properly.

- Cost of upgrading equipment and facilities.

- Managing large amounts of data and exceptions.

- Incompatible standards and lack of interoperability.

THE SYSTEM IN ACTION

The right side of Figure 4 shows the Phoenix storeroom and some of the items that are routinely stored there – seat cushions and EEMKs (Enhanced Emergency Medical Kits), for example. Each item has a barcode RFID label and, when that EEMK or the seat cushion or headrest or whatever part is needed, the mechanic walks it out of the storeroom. The photo on the left shows the RFID antenna pointing directly down. It scans the tag as the mechanic walks through the door.

Figure 4

That same antenna and philosophy applies when parts are being received from Seattle in a restock: when the mechanic walks in the storeroom with those parts, the antenna will read those tags and complete what we call a ‘transfer order’ in TRAX of the material going from Seattle to Phoenix. It completes the whole transaction electronically, just the same as a human would do but with a lot less work.

INVENTORY ACCURACY

At the moment, inventory accuracy is dependent on physical inventories carried out by our stores agents on a monthly basis and on mechanics reporting when they have used a part and which part they have used. Once we have the RFID technology in place, we hope to reduce the number of physical inventories we conduct from one per month to once every six to 12 months. We also expect a significant change in the discrepancies that we see at the different locations. We’re looking forward to these changes and I am very confident that, once we go-live with the new system, it will help us reach our goals.

COST SAVING

We expect to realize cost savings in several areas with the new technology. It will be possible to work with a reduced inventory because we won’t need, for example, ten EEMKs in Phoenix, if we know exactly when one was taken from stores and that another one is on the way. We can probably get by with a lower stock of, say, four or six or whatever is deemed reasonable. Historically, we have had to keep a lot of inventory on hand in the system based on ‘worst case scenarios’ and the ability to get parts to certain location. For example, we don’t keep a huge inventory at outstations such as Fairbanks, Alaska; it’s more of an emergency inventory with the type of parts that might be needed to get a plane back our hangar in Anchorage. But, in the future, with the RFID system, we may increase that inventory a little in terms of range of parts held but reduce the quantity of any particular parts types. Having less inventory items will mean lower costs to manage that inventory.

As far as manpower is concerned, we may hire a stores agent in Phoenix within the next one to two years to help manage re-stocks as well as manage the storeroom, however there is nothing definitively planned at the present time. With the RFID system, it might be possible to operate without an agent and still be very accurate by having someone get to the outstation storerooms once a month to complete a hands-on inventory for validation. But we’d like to have an agent in place moving forward to ensure that everything continues as it should and is 100 percent accurate. Also, there will be other stations where that would be the case.

Additionally, we are anticipating increased employee accountability and performance with the badging RFID linking employees to transactions. The RFID system will give us valuable information when it comes to tracking what happens to parts, turn-ins, or similar information.

THE PROCESS

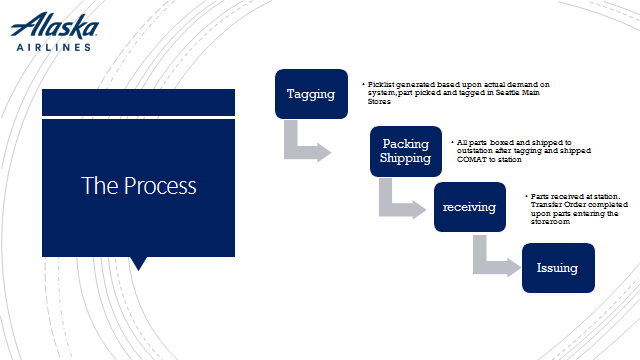

The process starts with tagging and runs right through to issuing (figure 5).

Figure 5

Alaska Airlines’ home base is Seattle so, when we do RFID to Phoenix this is what it will look like:

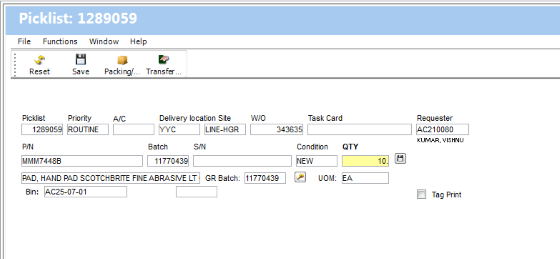

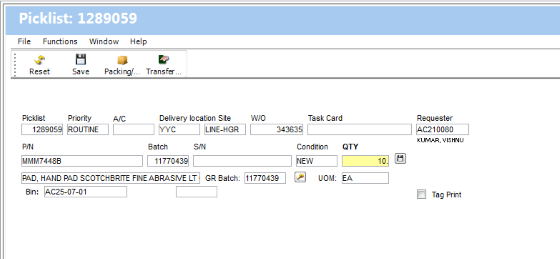

- Phoenix employees take the part; use of the part is noted in TRAX with the inventory debited; a signal is sent to Zealous to authorise the re-stock and the picklist prints in the warehouse location on an RFID enabled printer (a topic in its own right but it works well once up and running with the right drivers).

- The labelled parts are put in a box and shipped to Phoenix where, when they arrive, the mechanics know to carry them through the door with the RFID antenna ensuring that inventory transactions are accurate. Mechanics might not know, for example, that there are thirteen parts in a box, but the stock materials managers in Seattle do know that and can manage that to make sure that all thirteen items are caught by the antenna. They could then intervene if it did not happen. There’s a process in place to manage that electronically. This is why it’s the mechanics that put the materials on the shelf during receiving. It allows the antenna to pick them up and close the transfer order. We’ve tested this multiple times with worst case scenarios – we’ve even tried to trick the system by hiding parts cases but every time, everything in the box has been picked up, which is impressive.

- Issuing is the last step of the process; getting the part that’s needed, when it’s needed, to the mechanic that needs it.

By integrating the RFID system with TRAX, the following processes are automated:

- ISSUE Transaction: There’s nothing to do other than walk out of the storeroom, which alerts TRAX that the part has been issued.

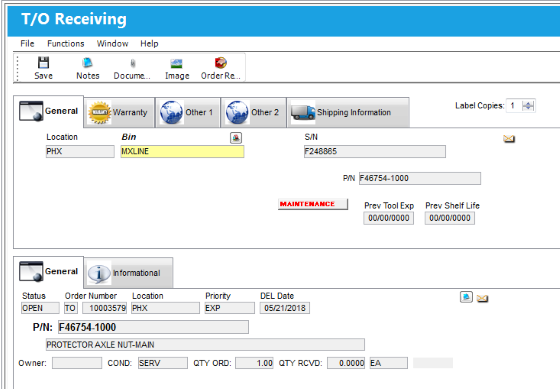

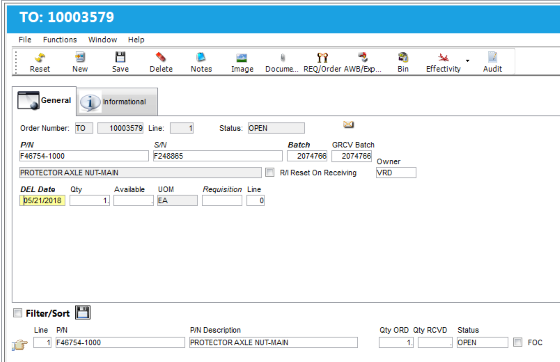

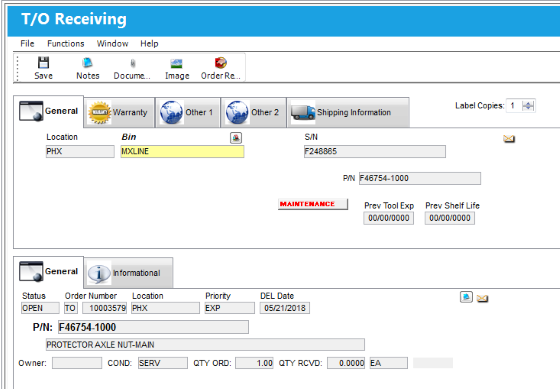

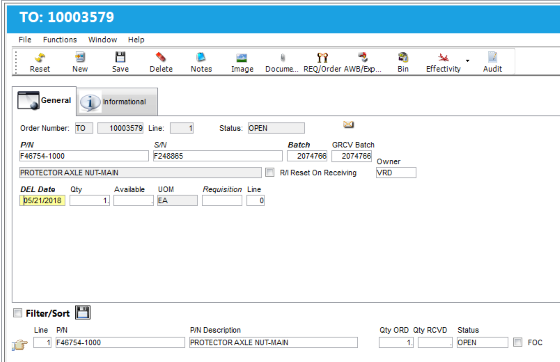

- TO (Transfer Order) Receiving: When the box arrives in the outstation, it goes through the storeroom door, the antenna picks it up, and now those parts have been received, so the transfer orders in TRAX are closed.

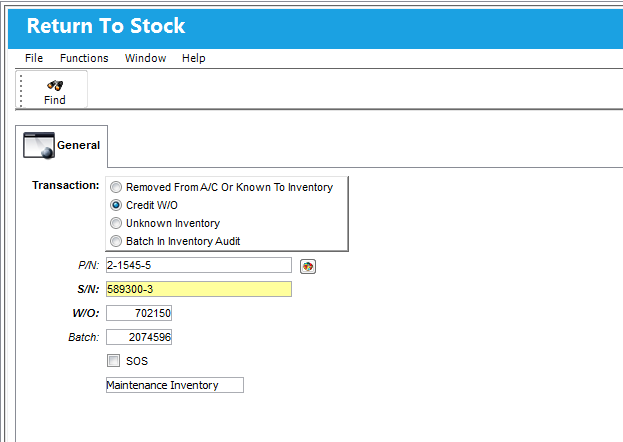

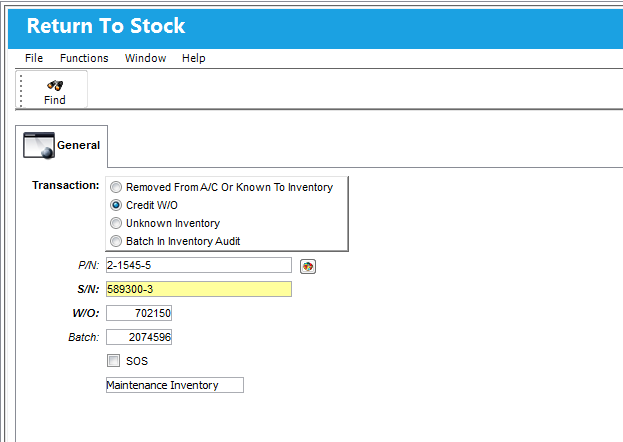

- RTS (Return to Stock): sometimes the question will arise that the mechanic took, say, four parts to the aircraft but only needed two of them; when he or she returns to the storeroom, the system is smart enough to know that, with the two parts that were brought back, they have to be RTS and put back on the shelf for use. Alaska has business rules in place that aim for mechanics to understand and do the right thing with the material. Our mechanics have become good at putting used RFID tags into a garbage can outside of the storeroom to avoid a used tag in their pocket to keep going into and out of the store through the antenna door.

- RTS Unserviceable

BUSINESS FLOW

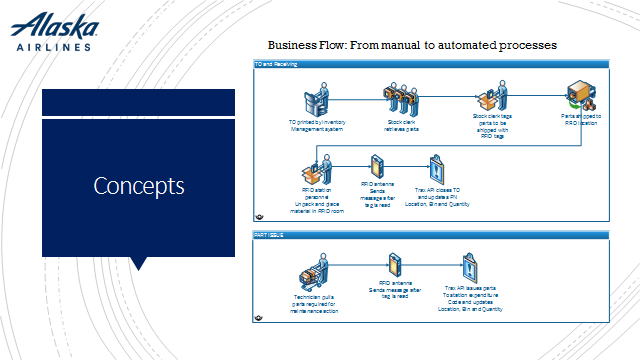

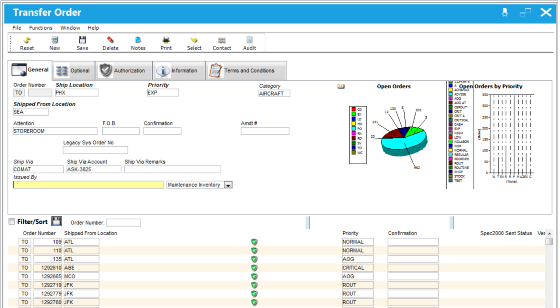

Looking at figures 6 and 7, all the touch points can be seen at the top of the infographic; printing the picklist, picking the parts from the shelves, boxing them up, putting the RFID tag on them, and shipping them to the location where the TRAX API picks it up via the antenna and closes the transaction.

Figure 6

Figure 7

It’s a lot smoother and easier than the manual process. Within TRAX it will do both transactions, i.e. for serviceable and unserviceable material. The key for serviceable versus unserviceable parts is to make sure the materials are separated. We have a separate location for unserviceable materials, especially ‘off units’, the rotables that we utilize. We haven’t worked out exactly what we want here in terms of RFID on rotables, which have a lot of information available. Also, we haven’t added the information for time constraint parts and shelf-life items. We have the ability to include that within the system but have not done so at this time. In fact, at the time of writing, we have filled only five fields of what could be up to a hundred fields on an RFID tag.

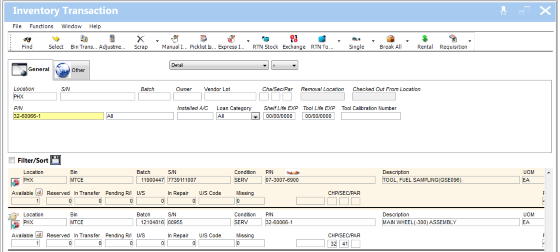

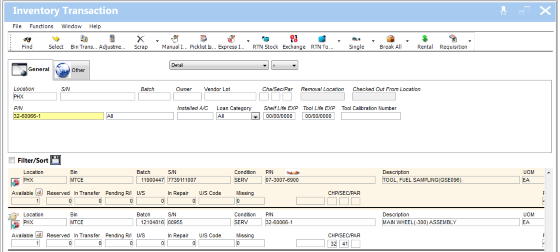

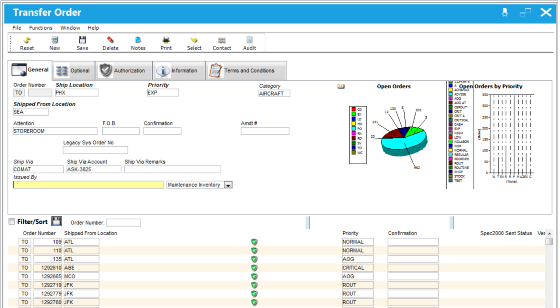

SOME SCREENS USED IN ALASKA’s NEW INVENTORY MANAGEMENT SYSTEM

A number of transactions were referred to in the article and here are the screens associated with those actions. The screen titles are self-explanatory.

Obviously, the RFID program at Alaska Airlines is a work in progress, but we are making good progress towards a much smoother and more capable inventory management system for our future.

Contributor’s Details

Jim Parish

Jim is an aerospace supply chain and maintenance expert with 35+ years of leadership and technical experience. He thrives on building teams that deliver results and positive financial outcomes in a mission-focused collaborative work climate. He has built a large portfolio of successful change initiatives keeping pace ahead of industry standards and instituting best practices within large organizations. He is the General Manager, leading the Material, Stores and Distribution Group at Alaska Airlines in Seattle Washington.

Jim is an aerospace supply chain and maintenance expert with 35+ years of leadership and technical experience. He thrives on building teams that deliver results and positive financial outcomes in a mission-focused collaborative work climate. He has built a large portfolio of successful change initiatives keeping pace ahead of industry standards and instituting best practices within large organizations. He is the General Manager, leading the Material, Stores and Distribution Group at Alaska Airlines in Seattle Washington.Alaska Airlines

Alaska Airlines and its regional partners fly 44 million guests a year to more than 115 destinations with an average of 1,200 daily flights across the United States and to Mexico, Canada and Costa Rica. Ranked ‘Highest in Customer Satisfaction Among Traditional Carriers in North America’ in the J.D. Power North America Airline Satisfaction Study from 2008 to 2018, Alaska Airlines maintains a young fleet of 155 Boeing 737 aircraft, 69 Airbus A320 family aircraft, 45 Bombardier Q400 aircraft, and 11 Embraer 175 aircraft.

Alaska Airlines and its regional partners fly 44 million guests a year to more than 115 destinations with an average of 1,200 daily flights across the United States and to Mexico, Canada and Costa Rica. Ranked ‘Highest in Customer Satisfaction Among Traditional Carriers in North America’ in the J.D. Power North America Airline Satisfaction Study from 2008 to 2018, Alaska Airlines maintains a young fleet of 155 Boeing 737 aircraft, 69 Airbus A320 family aircraft, 45 Bombardier Q400 aircraft, and 11 Embraer 175 aircraft.

TRAX

TRAX Maintenance is a completely integrated product, which brings many associated benefits. Organizational efficiency gains can be substantial when using the software. Customer return on investment is quickly realized and many examples can be provided. Consistency throughout all modules makes cross-training personnel much easier. TRAX Maintenance has been selected by over one hundred and fifty airlines worldwide with fleets consisting of all types of aircraft.

TRAX Maintenance is a completely integrated product, which brings many associated benefits. Organizational efficiency gains can be substantial when using the software. Customer return on investment is quickly realized and many examples can be provided. Consistency throughout all modules makes cross-training personnel much easier. TRAX Maintenance has been selected by over one hundred and fifty airlines worldwide with fleets consisting of all types of aircraft.Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.