Articles

| Name | Author | |

|---|---|---|

| Column – The iPad is a MacGuffin | Paul Saunders, Solution Manager, Flatirons Solutions | View article |

| Delivering aircraft performance | Adrian Forbes, Manager, APS Production, and Geneth Daley, Director, Aircraft Performance, Navtech, Inc. | View article |

| Case Study: Modern workflows to publish Operation Manuals on EFBs | Torsten Machert, Managing Director, EasyBrowse GmbH, and Lutz Kohlert, Office Coordinator Postholder Operations, Germania | View article |

| Fuel management is well worth the effort | Graham Smith, Analytical Capability Engineer, and Siow Litingtung, Fuel Consultant – Optimized Systems and Solutions (OSYS) | View article |

Fuel management is well worth the effort

Author: Graham Smith, Analytical Capability Engineer, and Siow Litingtung, Fuel Consultant – Optimized Systems and Solutions (OSYS)

SubscribeFuel management is well worth the effort

It isn’t only the savings that airlines will appreciate but, as Siow Litingtung Fuel Consultant and Graham Smith Analytical Capability Engineer at OSyS explain, the opportunities to improve business behaviours and company reputation

Challenging times

The airline industry today faces a number of challenges that demand innovation in a range of operating areas. The market, if not hostile, is certainly not an area for operating an airline in anything but the most efficient and effective manner. Reduced demand, high oil prices, climate change initiatives, fierce competition and a heightened risk of passenger compensation claims have combined to create the conditions for a very challenging environment. At the same time, the industry has to focus on improvements for which ‘getting it right’ will more or less be taken for granted, while failure can result in loss of business and reputational damage.

There is an absolute requirement to deliver a predictable, planned and safe operation whilst also continuously developing commercial innovation. This must be achieved under the spotlight of public scrutiny that expects value for money and an increasing interest in environmental credentials. Such a public focus is quick to reveal any imperfections in an airline’s safety and quality performance, whether these are real or perceived.

In order to thrive rather than simply survive in these difficult conditions, airlines, like any successful businesses, will need to search for differentiators; things that clients will value and that can be delivered efficiently. To do this they will need better information on which to base improved decisions and the key to better information will be good quality data. Bearing in mind that past behavior is often the best indicator of future behavior, decisions can be taken on the evidence of what has happened rather than a guess as to what might happen.

One thing that can support the creation of a differentiator and improve the public’s perception of an airline is a well-managed and effective fuel policy. If costs are better managed the opportunities to offer passengers attractive terms are improved. It can also support how ‘green’ an airline’s public perception is, as a good fuel management policy will reduce fuel burn and emissions; many airlines highlight the benefits of their fuel initiatives in shareholder reports and promotional material for customers.

OSyS VISIUMFUEL™ Dashboard

Managing and controlling operational fuel usage through the use of an IT system is becoming accepted practice within the airline industry. The benefits are well documented and best practice is evolving apace. So what are the next steps in terms of operational efficiency that can be leveraged from the data being gathered? To understand this fully we’ll need to investigate the possible unintended consequences that can flow from fuel management decisions. We’ll need to explore the benefit of targeted operational fuel usage messaging for individual stakeholders and the ability to improve fuel purchasing effectiveness by the generation of accurate future fuel burn forecasts.

Unintended consequences

Discretionary fuel management is a well-known ‘best practice’ area where an airline can save weight and therefore fuel burn. Firstly, by offering the pilot better quality decision support information, the uplift of excess discretionary fuel can be reduced. Secondly, suitable analysis of past data may increase confidence in the accuracy of the planned burn quantity, so that volumes of contingency fuel can be reduced. However, when it has been suggested to pilots that they should simply reduce the levels of contingency fuel, without any commensurate improvement in information being offered to support such a change, it has not been very popular with them. When the same policy has been accompanied by some effort at engagement and an endeavor to achieve buy-in from the pilots, that has sometimes initially reduced fuel uptake but in the longer run this improvement has not been sustained.

Only when the initiative has been accompanied by an effort to help pilots understand all the data that contribute to fuel management, and that by using that data to create an operational model it is possible to avoid the risks, have successful outcomes been achieved. In other words it is important to address the pilots’ immediate concerns and to work with their underlying professional ethos over the longer term.

Routing analysis

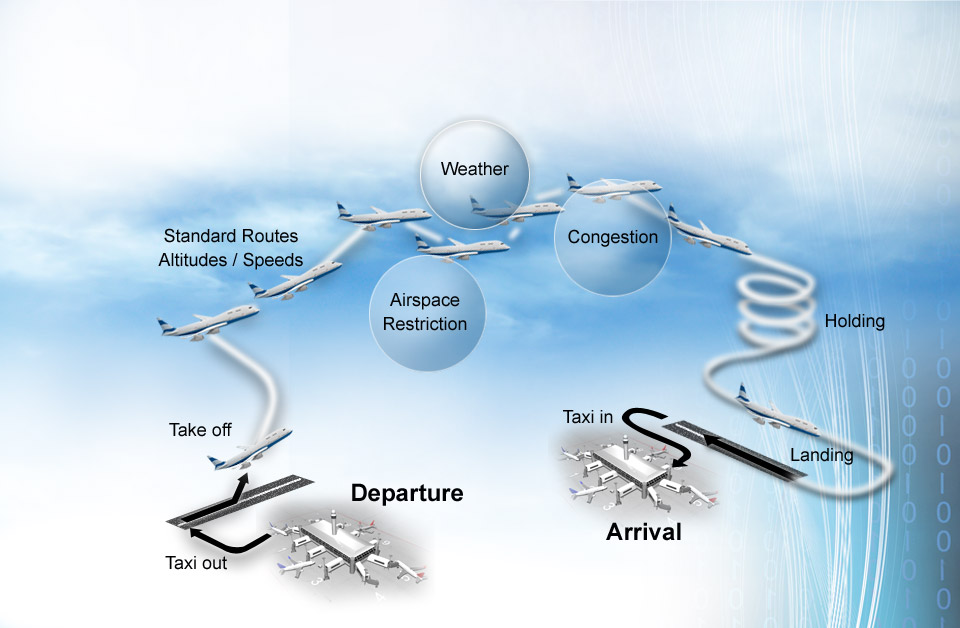

Routing analysis is a first step in understanding the factors that contribute to the deviation of the actual fuel burn from the flight plan value. There are a number of elements that affect the fuel efficiency of a particular route. As the illustration below shows, some of these factors are a result of decisions made by the airline, while others are imposed on the airline but need to be dealt with as efficiently and safely as possible.

Routing analysis is a first step in understanding the factors that contribute to the deviation of the actual fuel burn from the flight plan value. There are a number of elements that affect the fuel efficiency of a particular route. As the illustration below shows, some of these factors are a result of decisions made by the airline, while others are imposed on the airline but need to be dealt with as efficiently and safely as possible.

A commonly used approach is to examine the average variation of fuel burn from plan to identify which are the under-burning and over-burning sectors in the airline’s network. Although this is a useful first step, it can be difficult to make policy improvements on this basis unless further steps are taken to understand the underlying factors. This is because the different flight routing options for each sector will be subject to different influences and risks and therefore will show different burn characteristics; one track on a sector, because of a number of outside factors, might naturally generate less fuel burn than another. An analysis that takes into account the different tracks used at different times can highlight shifts on a given sector due to elements such as traffic congestion, seasonal effects and even airspace coming in and out of use. Analysis of this information will generate the next level of understanding and allow users to assess in more detail the likely risks that the fuel carriage policy for that sector must take into account.

If, from the information above we can begin to generate some expected fuel loads and burn profiles then we can also calculate how much fuel should still be on board at landing (taking into account the need to maintain safe reserves, of course). A comparison of the actual to ideal fuel on board at landing will then provide a good idea of where savings can be made. When targeting flights for fuel conservation measures it will be best to select those routes with the highest flight frequencies and the biggest burn bias, as these will yield the largest cost savings.

Having built a historic data analysis of this quality, we can begin to develop some ‘what if’ scenarios. For instance, what would happen if we removed the entire discretionary fuel load on a particular sector using the historic data set to validate that policy decision? We should be able to develop a graphic representation that would show us the corresponding reduction in the excess fuel left at landing and the margin to safe reserve levels, allowing an informed judgment to be made on a safe and efficient level of fuel reduction.

Engine washing

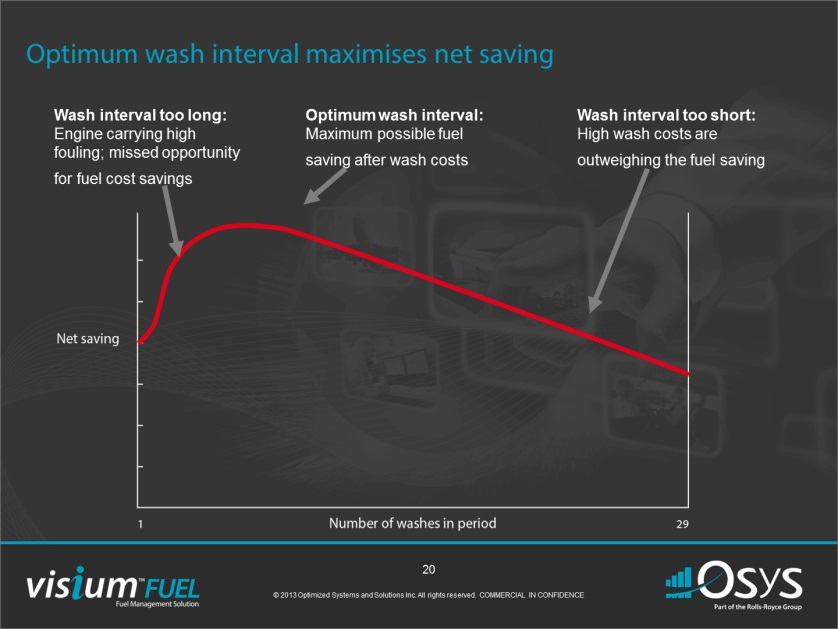

It is well-known that washing an engine reduces its fuel consumption and that instituting a regular engine wash program across the fleet can yield a useful fuel saving. This saving can be quantified by collecting and analyzing the ‘delta fuel flow’ information reported by the engine health monitoring (EHM) or aircraft performance monitoring (APM) systems. Typically, on the date the engine is washed a step decrease in fuel flow appears. After the wash there will be a steady accumulation of fouling on the engine compressor during the subsequent in-service period and that will be accompanied by a steady increase in fuel flow. For an operator to maximize the benefit of the wash program, we need to use this data to find the frequency of washes that maximizes the net value of fuel cost savings after accounting for the cost of washing. The rate of performance deterioration will depend on a number of factors including the age and condition of the engine, atmospheric conditions and pollution levels in the operator’s location, flight duty (short haul or long haul) and the climb and descent profiles used.

OSyS has developed an algorithm (patent pending) which tracks the deterioration rate of each engine and by using additional information such as the wash cost, the fuel price and the annual utilization rate, calculates the optimum wash intervals on an engine-by-engine basis. As can be seen from the following illustration, selecting the right wash interval for each engine maximizes the net cost saving; applying this technique across the operator’s fleet can result in significant savings compared to an arbitrary wash interval.

But calculating the ideal engine wash interval is only half the story: airlines will also need to deliver that wash schedule in the real world. Of course, on occasions it won’t be possible to wash an engine on the optimum date – perhaps there will be no capacity in the hangar or the aircraft might not be available at that time.

But calculating the ideal engine wash interval is only half the story: airlines will also need to deliver that wash schedule in the real world. Of course, on occasions it won’t be possible to wash an engine on the optimum date – perhaps there will be no capacity in the hangar or the aircraft might not be available at that time.

This is where a wash planning program can help by calculating how much cost saving has been foregone at the fleet level by missing optimum engine wash dates. This information can be fed back into the wash management initiative to help drive continuous improvement; actual results may be reviewed against the planned optimum to see whether any improvement is possible and, if so, how it can be realized. If combined with operation and maintenance scheduling data to identify and manage aircraft availability, further opportunities for cost optimization may be exploited.

Such a program requires robust data collection but can deliver clear operational recommendations; when to wash, regular assessment of the business benefits achieved by that program, and year-to-year monitoring to ensure that the value of the initiative is maintained.

Fuel purchasing – achieving an accurate fuel forecast

There are a number of factors that affect fuel burn. The type of aircraft being flown, and the performance of its airframe and engine, might be regarded as the baseline for fuel burn and weather might be regarded as an outside factor beyond the control of the airline. But there are other areas that operators can alter to affect fuel burn. They can determine routing, manage payload, apply different flight techniques and vary altitudes; all of these have an effect on fuel burn even before taking into account other fuel saving initiatives.

Consideration of these factors when analyzing fuel burn can help the airline gain a better view of how fuel is consumed, on which route and why. It should then be possible to develop a fuel policy that balances the needs of regulators, legislation, market attitudes and the challenges mentioned at the beginning of this article with the needs of a commercial airline.

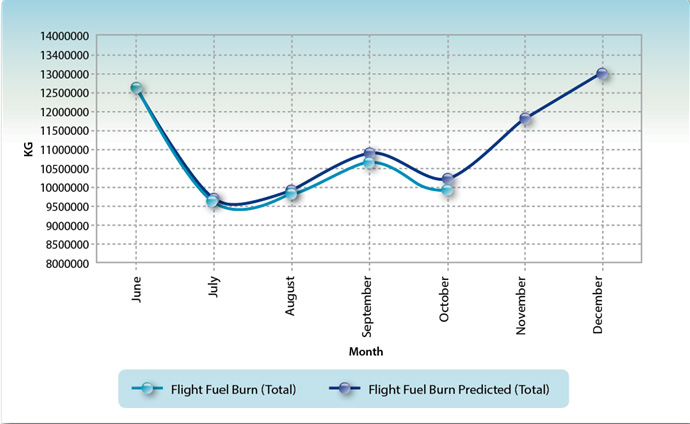

An accurate fuel forecast will mean better operational budgets and planning. The illustration below shows a well-constructed fuel forecast matching the actual burn in the early months.

As time goes by, a deviation does appear, albeit a positive one. This usually means that an airline has decided to introduce additional measures to generate further fuel savings, such as the engine washing initiative discussed earlier. The size of this improvement may be compared against the expected saving for the individual initiatives in force during the period, while forecasts for future years may be updated to reflect the increased fuel efficiency characteristics of the operation.

Summary

Airlines operate in a highly competitive and unforgiving business environment, but an effective data analysis program can be a powerful ally in managing and optimizing the efficiency of the operation. Used appropriately, data is the key to unlocking complexity, providing insights into the current state of the business, identifying and quantifying potential cost reductions and underpinning accurate forecasts. This enables better operational planning, budgeting and evidence-based decision making.

Operators who have an effective fuel conservation program through a mature analytical platform supported by significant airline and aviation experience, have not only managed to save fuel costs, but have also fed improvements into other aspects of their operation. This has improved passenger experience as well as the perception of an airline maintaining high corporate and environmental standards. In today’s challenging environment, that is an increasingly valuable outcome for any operation.

SIOW LITINGTUNG

FUEL CONSULTANT – OPTIMIZED SYSTEMS AND SOLUTIONS (OSYS)

Siow Litingtung leads operational fuel modelling for OSyS. Prior to assuming his consultant role, Siow spent 10 years within Rolls-Royce plc. holding a variety of technical performance roles within the Civil Aerospace business for large engine programs, as well as corporate & regional and military engine projects in Rolls-Royce North America. He was also Fuel Conservation Manager for easyJet, managing a broad, cross-functional program of fuel conservation initiatives to deliver fuel burn efficiency improvement.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.