Articles

| Name | Author | |

|---|---|---|

| Integrated systems or integrate your systems | Ingunn Ingimars, IT Consultant, Aviation42 | View article |

| Air Canada Case Study: Speaking a Common Language; improving communications | Douglas Bernie, Manager of Airline Operations IT, Air Canada | View article |

| Case Study: Much more than a new EFB – the AeroLogic iPad EFB project | Wolfgang Sperber, Administrator EFB and Operations, AeroLogic, and Jürgen Gläser, Product Manager, T&A Systeme | View article |

| Fuel Management: a piece of cake or an art? | Gesine Varfis, Managing Consultant, Lufthansa Consulting | View article |

| Column: The World according to IT and me | Paul Saunders | View article |

Fuel Management: a piece of cake or an art?

Author: Gesine Varfis, Managing Consultant, Lufthansa Consulting

SubscribeFuel Management: a piece of cake or an art?

Gesine Varfis, Managing Consultant at Lufthansa Consulting explains the current status of cost Index Operations and tactical in-flight fuel management tools.

There is a straight forward answer to the question posed in the title above: while Cost Index (CI) setting is a piece of cake the determination of CI as well as tactical in-flight fuel management is an art. By definition artists are ‘able by virtue of imagination and talent or skill to create works of aesthetic value’ the only difference with CI setting is the definition of what value is created. However, as with works of art, the monetary value of CI Operations is hard to predict, difficult to manage and not easy to measure and benchmark. Although in-flight mission support as well as pre- and after-flight fuel management tools are available on the market and, although the predicted cost savings are in the millions, airlines have not joined the CI cost saving mania to realize these savings. Why not, at a time when one cost saving initiative and fuel burn reduction program follows closely on the next?

Currently, after the flight plan has been issued and until the aircraft lands, airlines fly relatively ‘blind’ as far as decision support tools are concerned. Compared to the capabilities of today’s analytical tools and what data could be made available, tactical fuel management is very much hands on, like APU versus GPU, single engine taxi, engine wash, etc. At the same time, the tools available on the ground for strategic schedule planning, flight planning, the evaluation of aircraft and engine performance, etc. are very sophisticated. The Electronic Flight Bag (EFB) is always mentioned in line with fuel management and the EU Emissions Trading Scheme (ETS), but this might be misleading. Airlines mostly apply EFB solutions to provide the crew with a paperless cockpit. In most cases EFB solutions are not used for tactical flight planning, but have replaced the tons of paper in the cockpit (aircraft library, route manuals, flight folder, tech log, journey log, etc.) with the exception that weight and balance calculations are still performed on paper.

In respect to analytics there are airlines which do not even allow the analysis of flight profiles with the related fuel burn, while other airlines analyze FODA (Flight Operations Data Analysis) data and rank, even paying their crews according to fuel savings. On the other side, the analysis of fuel-burn per route is not trivial, due to the different influencing factors like weather, payload, aircraft, engines, routing, flight levels (climb, cruise and descent), in-flight routing changes, etc. A holistic Key Performance Indicator (KPI) which covers the evaluation of cost and fuel burn in one single figure has not been identified, so benchmarks per route have their limits. Therefore the majority of airlines focus on the capabilities and commitment of their crews (the artists in our scenario) in addition to IATA’s (International Air Transport Association’s) published fuel saving action items. At present there are quite powerful pre-flight load and flight planning tools on the market. In comparison tactical in-flight fuel management as well as fuel burn analytic tools are still in their infancy and need to be developed further.

However, many airlines face the fact that the generation of massive fuel savings has been covered by the implementation of IATA recommendations and guidelines for fuel savings. The more or less unexplored field in the generation of fuel savings is the blank spot of CI related in-flight fuel management, which is now being explored by entrepreneurs from both the vendor and airline sides. In recent years CI has made it back to the top of the agenda in conjunction with in-flight mission support. Although there are no standards defined nor in-depth statistical evaluations or studies at hand, individual airlines have shown significant savings in relation to CI in-flight fuel management. The potential for savings with CI fuel burn are relatively vague: some studies mention 4–5 million USD, others indicate multiple millions of dollars each year or suggest percentages from 1% up to 10% per case. Case studies have shown that tactical CI management tools based on an EFB solution have saved up to 4% on average for regional operators and indicated possible savings of up to 2% for long-haul flights. There are airlines which have admitted that they have lost millions in wrong CI setting and others declare sophisticated savings only by setting a different CI standard, e.g. an A320 operator has saved 3.5 million EUR by changing the CI standard from 30 to 20. This translated into 33 kg fuel savings per flight in combination with an increase of 1.5 minutes per flight.

In-flight CI Operations have the potential to support the art of tactical in-flight fuel management. However, there are challenges which need to be tackled to generate these savings.

The piece of cake in CI Operations

Over the last decade, flight crews have entered the CI index into the Flight Management Systems (FMS) before a flight, based on manufacturer recommendation or individual company standards. The CI formula is straightforward: it has existed unchanged for years. Moreover, there is a common agreement that today the CI is the most important, key value, for advanced flight path optimization based on the following formula:

| CI = | Time cost ~ $/min |

| Fuel cost ~ $/kg |

By entering the CI into the FMS the CI index determines the fuel consumption relationship used during the flight; the trade-off between fuel burn cost against cost of time (cost of delay). It’s as easy as that: a high CI entered into the FMS determines faster flying with commensurately higher fuel consumption whereas operating with a lower CI the aircraft would take more time to arrive at the destination, but would burn less fuel. For index setting, a scalar from CI0 to CI max. is applied, representing maximum fuel conservation (CI0) and maximum delay recovery (CI max). Different FMS suppliers offer ranges from 0 to 99 or 999 (max).

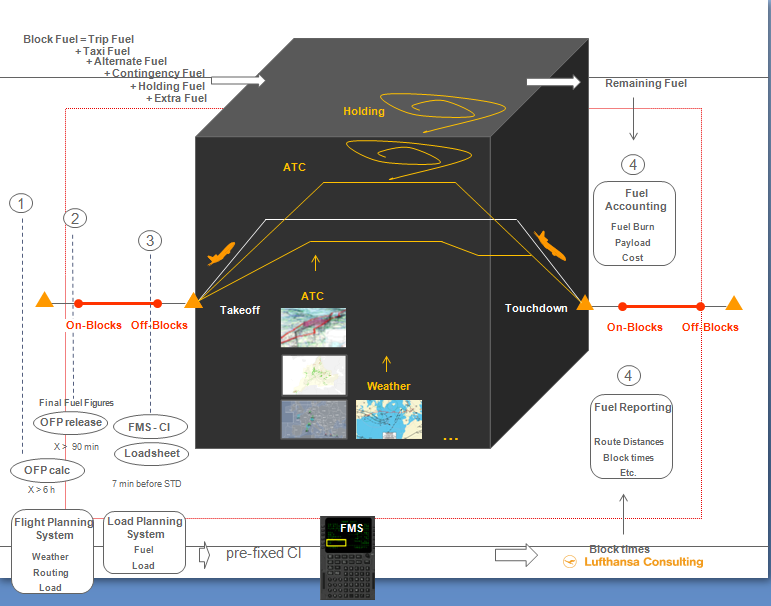

Figure 1: In-Flight Tactical Fuel Management is like a black box

Where the art starts

In 1998 Airbus referred to CI management as a concept that is often not taken into account: ‘CI itself is largely an unknown concept’ and ‘a large variation exists in how airlines actually use the cost index.’ This statement is as current today as it was in 1998 and, in 2007, when EuroControl performed its Innovation Research Workshop on dynamic cost index setting.

The acceptance of CI setting as an industry standard to allow in-flight fuel savings as well as delay recovery has never been questioned; however, where the art starts is not in the cockpit but with financial accounting. Currently there are no defined standards for cost of time and cost of fuel determination, nor are the traditional financial accounting tools which are available sophisticated enough to allow an easy cost analysis of time and fuel for an individual flight. Due to the current cost element, accounting route, aircraft based cost of time and cost of fuel calculations are quite a complex effort. This translates into the fact that many airlines apply cost assumptions, or historic averages instead of actual data. Especially in relation to the volatility of fuel price, budgeted fuel cost data or average data from last year will not determine an accurate CI index for a flight.

In general airlines have kept it simple by setting a company fixed CI based on maintenance and crew cost whereas direct operating airline cost should be differentiated into the following categories:

– Fixed;

– Cycle related;

– Time-related;

– Fuel.

The fixed and cycle related costs are usually not included in the CI calculation. However, with today’s cost accounting and controlling applications the tricky part is not the determination of fuel cost per leg, it is how to determine the time cost. It should be discussed whether crew and maintenance costs are good enough factors to determine cost of time. Today, airlines spend a lot of effort on delay cost management and passenger connection management. Therefore lost slot cost, new en-route charges, cost of delay and passenger missed-connection cost should be taken into account to determine a more accurate ratio of cost of time and fuel.

There is not one single best practice to follow for CI setting, nor has there been enough research to determine the right way of setting CI. What has been identified is that airlines have lost millions over the years by setting the wrong CI. However, the following CI determination is applied:

– Fixed CI;

– Dynamic CI.

The CI setting applied is further differentiated by the following company setting rules:

– CI over all fleets (narrow body – wide body aircraft);

– CI for long haul and short haul flights;

– CI for different aircraft types;

– CI for delayed short haul and long haul flights;

– CI for flight levels;

– CI according to hour limits (e.g. 4 or 6 hours and above);

– CI for climb, cruise and decent.

The vagueness in the index determination explains why many airlines have not taken the initiative in implementing in-flight tactical management tools. The imprecision of the CI cost determination translates into the fact that what cannot be measured cannot be managed, nor can it be benchmarked or analyzed in a sophisticated manner. Up until now, CI operations have not been based on an industry standard in terms of calculation and quantification. However there have been airlines which have taken initiatives to allow more sophisticated CI determination to be developed in order to further allow CI in-flight mission support. Based on these efforts the following CI categories have been defined to classify possible CI evolutionary steps in relation to in-flight fuel management tools:

| Classic Fixed Cost Index

CI |

Dynamic Cost Index

dCI |

Dynamic Delay and Connex Cost Index

d2C2I |

| – Maintenance cost (time related);

– Crew cost (cockpit and cabin). Other classic CI variants include additional cost such as: – Passenger service; – Lease charges; – Navigation charges; – Fuel and oil. NO FIXED COST. Mainly applied as a fixed company standard with planned or average standard figures per annum. Pure FMS CI setting applied. |

– Variable maintenance cost;

– Variable crew cost (cockpit and cabin). The difference is that the fuel cost is differentiated further to keep the volatile kerosene price as current as possible: – for every month; – for every destination. CI calculation per… – Sub fleet; – Destination / route. Mainly applied as a continuously pre-calculated value stated in the original flight plan (OFP). Here many flight planning tools offer additional applications. Only with dynamic CI will the implementation of in-flight performance calculation tools starts to make sense. |

The dynamic delay and connection cost index standard is split into the application of two calculation standards:

– One for on-time departure (dCI); – The other for delayed departures (d2C2I). For delayed flights the cost of delay are calculated by taking the following delay costs into account: – Misconnection cost (vary between 100 – 140 EUR / PAX); – Passenger value index for connecting PAX and customer value (class, status); – Delay cost, e.g. additional slot cost, parking, ground handling, etc. This translates into individual CI setting according to individually calculated delay cost. The sequence of cost data updating is defined as follows: – Fuel prices updated daily; – Staff cost including; overtime hours (updated daily); – Technical cost and others updated annually. In any case, the d2C2I setting is complemented by a prioritization of flights, consulting with cockpit crew and cost of delay investigation (connex PAX, aircraft rotation, crew rotation) to allow a tailored CI setting for a delayed flight. |

What do in-flight fuel management tools offer?

The tools currently on the market supplement the FMS with more powerful calculation and scenario options. The FMS has never been designed to perform scenario calculations and it is certified with the introduction of the aircraft and unlikely to change before the end of the aircraft’s life. The performance calculation potentials are very limited. Scenario calculations for different trajectories, flight levels, weather and wind conditions are not supported. Moreover the FMS is limited in relation to the number of flights and routes to be stored and, amongst other limitations, it cannot take the latest wind information into account. Therefore the only option to enhance tactical in-flight planning today is the introduction of mission support and/or in-flight performance calculation applications as part of the EFB to allow the re-calculation of routes, speeds, flight levels (in relation to the key fuel burn drivers like weather), Air Traffic Control (ATC) and delay causes without limitations. Today’s tools allow the in-flight calculation of the most cost-efficient flight trajectory complemented by a re-calculated CI for the FMS.

Where the art needs to provide the artist with an environment which fosters creativity

Today the tools related to CI are mainly located in the area of pre-flight planning. However, there are airlines which still prepare their flight plans hours before briefing some up to six hours before, others apply fixed routes and most of today’s airlines do not relate any connection, delay cost or missed-connection cost as mentioned above, although CI is also about delay recovery. It is strange to see that, on the ground, large network carriers invest in highly sophisticated Hub Control Center (HCC) tools where every passenger connection is evaluated in terms of passenger worthiness and missed connection cost versus connection saving action costs. The tools applied recalculate the different options based on estimates and calculated on block times to save passenger connections either via ramp transfers or approach and taxi prioritization amongst others, and yet, in the cockpit, time stands still.

To be fair, improved CI determination complemented by an in-flight fuel management application is a more complex undertaking than expected. For each of the CI categories defined above certain IT and communication infrastructure needs to be established to generate the full benefit.

| Classic Fixed Cost Index

CI |

Dynamic Cost Index

dCI |

Dynamic Delay and Connex Cost Index d2C2I

Mission Support |

| Pre-Flight Application:

– Standard Flight Planning Tool; – Average cost accounting figures.

In-Flight Tools and Equipment: – For classic CI setting the FMS is sufficient.

After-Flight Tools and Equipment: – Fuel accounting tool. |

Pre-Flight Application:

– Sophisticated flight planning tool which allows the calculation of different flight plan options with an integrated CI calculation; – Detailed cost accounting figures based on a sophisticated costing solution.

In-Flight Tools and Equipment: – EFB class 2; – Communication of flight updates; – In-flight fuel management solution; – FMS.

After-Flight Tools and Equipment: – Fuel accounting tool; – Fuel reporting and analytics tool; – Block time analysis tool; – Fuel accounting tool. |

Pre-Flight Application:

– See dCI

In-Flight Tools and Equipment: – EFB class 2 which allows powerful analytics of the current flight situation automatically fed with flight update scenarios; – In-flight fuel management solution; – FMS.

In-Flight Mission Support (ground and/or): – Real-time updates of OFPs; – NOTAMs, Weather, ATC restrictions, etc.; – Inflight route optimization – Connection information and free text updates; – Improved calculated on block / arrival times. The communication infrastructure needs to cover full gate-to-gate communication and information exchange infrastructure via ACARS, data-link, SATCOM, GPS, gatelink, etc.

After-Flight Tools and Equipment: – See dCI |

Last but not least, to permit artistic creativity (to generate the calculated fuel savings) the industry needs an ATC infrastructure environment which supports in-flight tactical route, speed and flight level changes. This means that, even if highly sophisticated mission support and in-flight calculation tools are installed, the scenario calculation of other more economic options is irrelevant if these options are not available. The Intergovernmental Panel on Climate Change (IPCC) states that there is up to 12% inefficiency in the infrastructure, including Air Traffic Management (ATM). These limitations affect the industry massively:

– The fragmented European airspace still prevents direct routings;

– Available airspace is not used to its full extent due to lack of transparency and poor communication;

– Terminal airspace redesign, P-RNAV (Precision Area Navigation), CDA (Constant Descent Approach), RNAV (Area Navigation) approaches, etc. are overdue;

– Every day more than 20,000 flights need to be coordinated by more than 60 different ACCs (Airport Control Centers / Active Clearance Controls);

– Non-adherence to initial flight plans leads to ‘over-deliveries’ which result in wasted capacities in some sectors. Flights are not flying at the initial requested flight level (35% in 2008).

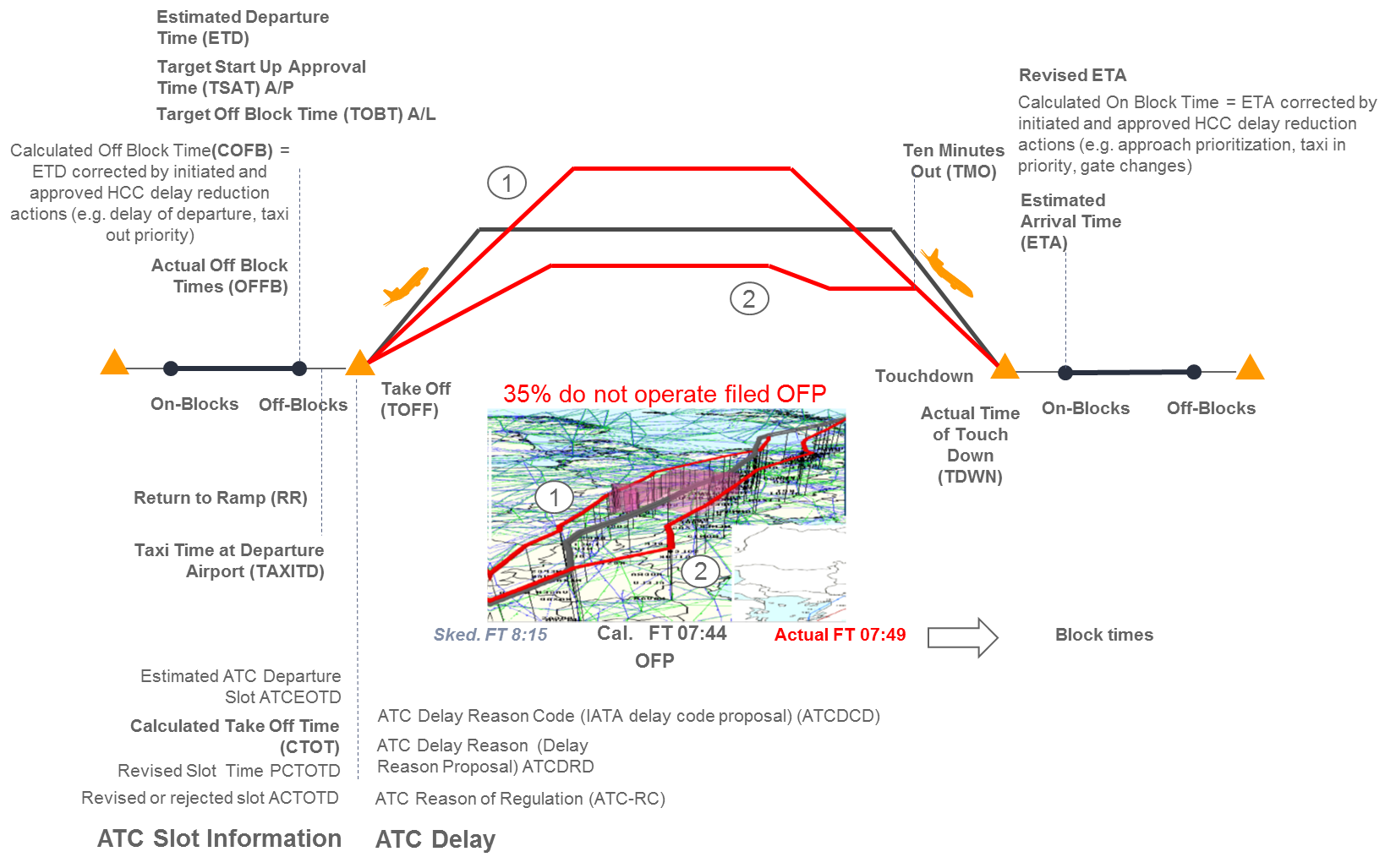

The first steps in evaluating routes and better time stamps are taken especially at departure; many new times are taken into account (see figure below). However airlines need to improve in time accuracy calculations also for arrival management and to fill the blanks for the in-flight time stamps.

Figure 2: Today’s time stamps need to be related to fuel burn and in-flight time stamps need to be addressed

The main issue to make CI and in-flight mission support more attractive will be ATC. SESAR (Single European Sky ATM Research) and IATA have introduced initiatives to pursue flexible airspace tracks with a focus on airports and terminal maneuvering areas (TMAs), plus the development of new procedures based on global navigation satellite system (GNSS) technology. At the same time airlines have started to tackle CI complexity together with mission support. With a holistic approach from different stakeholders in fuel saving, the black box of in-flight tactical fuel management will be opened and the innovation leaders will not only harvest but will lead in the generation of cost savings. However, due to the constraints in CI Operations an intelligent investment into tactical in-flight support tools will pay off.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.