Articles

| Name | Author |

|---|

White Paper: The fuel budgeting complexities

Author: Siow Litingtung and Simon Mayes Consultants, OSyS

SubscribeThe Fuel Budgeting Complexities

Understanding the complexity of fuel budgeting, say Siow Litingtung and Simon Mayes Consultants at OSyS, is a very important step towards mastering this critical process

Fuel Budgeting is a difficult, time consuming and potentially flawed process that has to be undertaken by all airlines but with few achieving any real degree of accuracy. Based on experience in the industry, we understand that fuel budgets are anecdotally inaccurate up to +/- 10%, which equates to a large financial impact for any airline.

Fuel budgeting involves collecting large volumes of data, related to operational fuel burn and from various sources, before turning it into a cost model to manage fuel expenditure. However, simply taking data from the previous calendar year as a baseline and adding a conservative factor to pad next year’s budget will rarely produce an accurate forecast for fuel expenditure. This inherent inaccuracy often results in the need for re-forecasting activity throughout the budget period. Static, two dimensional spreadsheets are generally the tool of choice for the current generation of airline fuel budget setters. This can result in a lengthy process, error prone, often frustrating for all stakeholders involved and, as often, not providing the required visibility across all factors that need to be considered in the budgeting process. Changes and variances to the budget are also difficult to manage with this process.

As an alternative, by using the right solution and taking advantage of all operational fuel data available, the process can be both dynamic and collaborative, leading to greater accuracy. Managing the operational data and understanding its complexity can, in turn, improve the underlying assumptions within a fuel budget. This supports better insight to be delivered to the right functions within an organization and for the necessary changes to be applied to generate the new budget more accurately. Additionally, any substantial variance from fuel budgets can be identified earlier and appropriate corrective measures taken to calculate a better forecast. Our experience at Optimized Systems and Solutions (OSyS) indicates that a typical fuel budget can include error in excess of 10%; however, by using analytics through a flexible, intuitive Fuel Management Solution (FMS), this can be significantly reduced.

%20FIGURE%201.jpg)

Figure 1

Manage your data

Airlines have a network of complex operational systems that contain direct and indirect fuel related information. Depending on the level of IT data integration, some of the fuel data (e.g. fuel uplift recorded on invoices) may be time consuming to extract and, even then, yield inaccurate or inconsistent results. Good data quality is critical to influence the right organizational behavior and it supports the correct assumptions required for fuel budgeting. An automated FMS can consolidate all fuel data into a single, trusted database with inherent tracking of data quality.

Understand the complexity

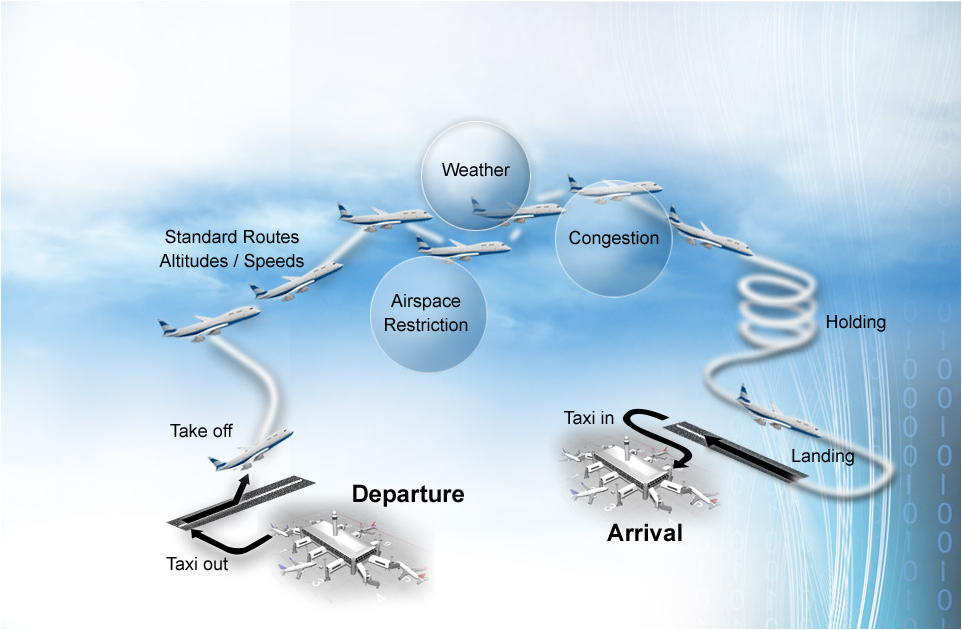

Airlines use various Key Performance Indicators (KPIs) to track and forecast fuel usage once the fuel budget has been set. Some, such as Burn per Block Hour, are simple measures that do not take into account many operational factors, and therefore, understanding their variances can be challenging. Some of most common factors that affect fuel usage are:

- Aircraft/Engine performance;

- Aircraft type changes;

- Fuel savings initiatives;

- Crew technique;

- Payload;

- Routing;

- Weather;

- Airspace restrictions;

- Congestion.

Understanding the complexity of all these factors will improve the assumptions and accuracy of fuel budgeting. Once a fuel budget has been set, managing the data complexity and reporting the impact of the variances are crucial to maintain forecast accuracy, and to indicate if and when re-forecasting becomes a requirement.

Figure 2

Apply changes to generate the new budget

Traditionally, a fuel budget is created by a wholesale regeneration of what happened in the previous year, but with some minor alterations. In order to better understand operational complexity, various functional teams are consulted for input:

- The Sales teams have targets for load factor and revenue, and to highlight any exceptional routes so that type changes and increased capacity can be accommodated in the plan.

- The Flight Operations team may have specific targets to reduce fuel consumption using methods such as improving pilot technique, reducing engine taxi fuel, promoting Flaps 3 landings when applicable and reducing the amount of discretionary fuel loaded.

- Marketing and Cabin Services may be changing the onboard service, increasing onboard sales or passenger convenience items.

- Engineering can target processes such as engine washing and aerodynamic cleanliness for fuel efficiency improvement.

Prior to issuing the fuel budget for the next season, many iterations involving all key stakeholders, are normal. The process can involve multiple, extensive ‘deep-dives’ into the fuel data and producing a variety of ‘what-if’ scenarios.

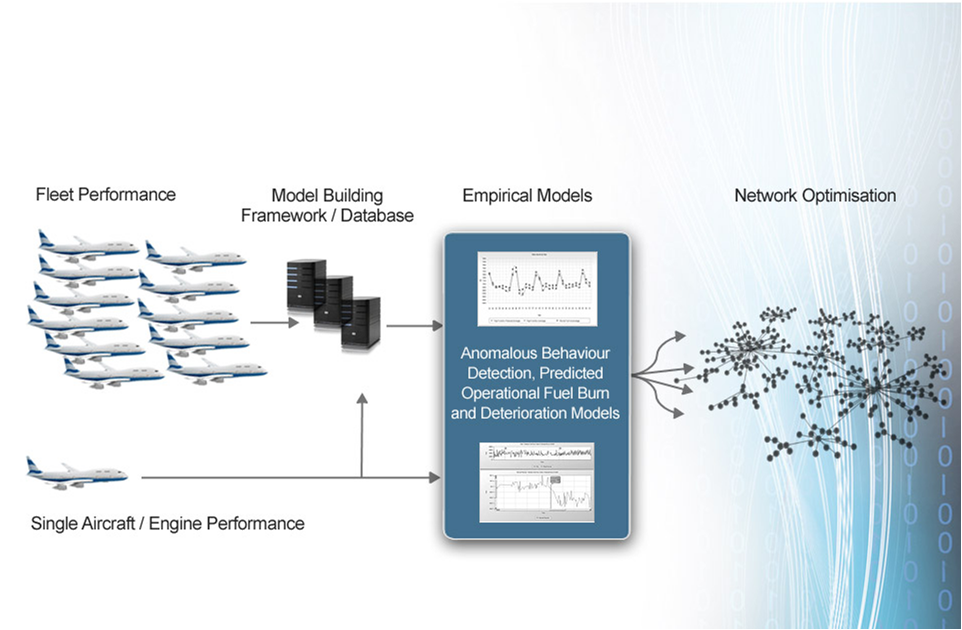

Performance deterioration of aircraft and engine assets do not often get the consideration that is necessary in fuel budgeting process but the engineering maintenance program for the fleet can significantly alter operational fuel burn signatures over the course of the season. Aligning the level of engineering maintenance and rework with the fuel burn targets for the next season develops a more comprehensive fuel budgeting picture.

%20FIGURE%203.jpg)

Figure 3

Initiatives such as single engine taxi can substantially impact fuel burn, and taking this type of initiative into account within the budgeting process, again, produces a more complete and accurate forecast.

%20FIGURE%204.jpg)

Figure 4

Additional considerations may involve comparing block times from previous schedule operations to this season’s program as slot times may have changed; this may potentially require flying faster to meet punctuality goals. As part of the iterative process, APU usage at individual airports may also have to be reviewed and optimized to take into account existing and future ground handling contracts to ensure cost effectiveness.

Beyond these examples and considerations highlighted, in reality there may be many more levers with varying impact on fuel which should be taken into account across an airline’s network, in order to appropriately generate a new budget. It is therefore much more beneficial to have a flexible, automated Fuel Management Solution with in-built modeling that easily manages the intricacies of creating and monitoring the budget, keeping sight of whether it is in line with strategic targets .Optimally, an FMS should capture the essence of operational complexity into one fuel budget value with the ability to adjust for operational forecast changes.

Understand and manage variance

Once the fuel budget has been established, the constant challenge to understand and manage variances to the budget begins. Invariably an approved fuel budget becomes outdated since it cannot reflect actual operational variables (e.g. more passengers were carried for a particular month than what was assumed in the budget and therefore fuel usage was higher). This ‘measure the measurement’ activity can be painfully time consuming. A robust FMS can easily help differentiate between any variance due to justified attributable causes as opposed to performance related inefficiencies that need to be addressed. Using an effective FMS will greatly facilitate communicating variances from the fuel budget plan (and their reasons) to the appropriate airline budget holders, thus reducing decision making complexity. This is best executed through an automated solution that can configure complex business rules to alert on non-adherence to best practice, or to track shifts in performance using predictive modeling capabilities – both at an individual asset and network wide level. Utilizing high quality, trusted data and model driven information provides insights to the efficiency and effectiveness of initiatives, and to policy adherence.

Figure 5

Summary

Better fuel budgeting using an automated Fuel Management Solution has obvious financial and operational benefits. With an accurate budget based on good assumptions, airlines will be able to cut out unnecessary expense, save money, and take intelligent action when variances occur. Therefore, they can maintain a sharper focus on keeping their business competitive by responding more quickly to changing customer needs, by maintaining an accurate fuel budget for planning purposes and by delivering actionable insights across the entire organization.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.