Articles

| Name | Author |

|---|

Case Study: Pegasus Airlines EFB: buy or build

Author: Mehmet Akverdi, EFB Technical Admin, Pegasus Airlines and Capt. Korhan Celik, Assistant Fleet Manager, Pegasus Airlines

SubscribePegasus Airlines EFB: buy or to build?

When Pegasus Airlines wanted a new EFB, the decision was, as Mehmet Akverdi, EFB Technical Admin and Capt. Korhan Celik, Boeing Type Leader explain, to build one that exactly matched their needs

Having developed our own EFB program at Pegasus Airlines, we’d like this article to offer readers a glimpse into what we have achieved and how we have achieved it as well as an insight into our EFB and how it works, our aircraft tracker and the dashboard that the whole solution uses for analysis. First of all, though, it will be useful to understand something about Pegasus airlines.

PEGASUS AIRLINES

The 5,000 employees at Pegasus Airlines deliver almost 3,000 flights a week and fly nearly 25 million passengers a year to over 100 destinations, including more than 70 international destinations in 40 countries (see route maps below). With its hub at Istanbul’s Sabiha Gokcen International Airport, Pegasus, founded in 1990, was the first low-cost airline in Turkey and remains the fastest growing. The business was acquired by ESAS Holding in 2005 and is a purely private company with the largest fleet in the region.

Pegasus International Route network

Pegasus Domestic Route network

As well as the named brand itself, Pegasus also has two subsidiary airlines: iZair, based in Izmir, Turkey and AirManas, based in Bishkek, Kyrgyzstan.

Pegasus flies 43 Boeing 737-800NG, plus 24 Airbus A320, 12 –CEO and 12 –NEO types; Pegasus was launch customer for the A320-NEO. iZair has seven B737-800NG and AirManas has two B737-800 plus one B737-400. In addition to the current 77 strong fleet across the businesses, a further 65 Airbus A320s are on order so that, by 2023 we expect the fleet size to exceed 150.

For a number of reasons, we decided to build our own EFB at Pegasus and, at the same time, we built an aircraft tracking system so that the airline can know where all its aircraft are at any time.

EFB AT PEGASUS

In 2015, Pegasus with Panasonic launched the electronic flight bag (EFB) project; a digital system that helps to create, manage and store the documents that pilots need during a flight. Before Pegasus had any sort of EFB, paper documents critical to navigational safety were stored in aircraft cockpits and, with a weight of up to 50 kilograms, they added to fuel burn plus every update had to be made manually at the cost of increased workload and higher expenditure – paper, printing and copying costs.

EFB improved in-flight efficiency for Pegasus, coupling the EFB software with the Panasonic Toughpad FZ-G1 10” tablet which has EFB certification and has been proven to withstand impact, water, dust, vibration and extreme temperatures, with a screen that can be read in direct sunlight.

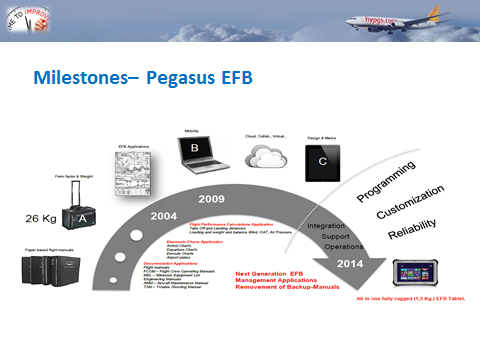

Figure 1

The journey to today’s EFB

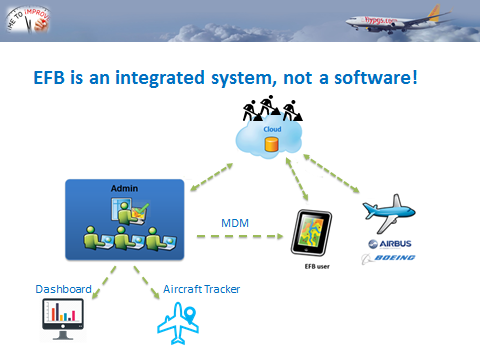

The Pegasus development and implementation team worked for more than a year to create a unique user-friendly system. In fact, the airline been using EFB applications since 2009 (figure 1) when we started to use a laptop in the cockpit before take-off and after landing but not enroute. Following the arrival of Cloud technology and tablets we started to use tablets in our cockpits with the introduction of the new solution. With Windows OS and Cloud technology we now enjoy a near flawless package that has become indispensable for all flights. We did look at EFB software from different vendors but we feel that EFB needs to be an integrated system, not just software (figure 2). Also, while off-the-shelf solutions might well take pilots’ views into account, they cannot involve them either as early or in as much depth as Pegasus was able to do when developing its own EFB solution. Once we had decided to build our own EFB, we worked very closely with the pilots as a result of which, the development team understood what the pilots thought and got a better understanding of the limitations in the software. Our requirements were limitless but the pilots enabled us to prioritize in a way that would support them. The team also learned in detail what the pilot was doing in the cockpit and what they needed.

Figure 2

Our solution includes an administration with a lot of ‘workers’ in our Cloud system who deliver service 24 hours a day, seven days a week. We can also manage the tablets on the aircraft from our administration using mobile device management (MDM). Furthermore, we can monitor and follow our key performance indicators (KPIs) and our aircraft from the administration using the Pegasus Dashboard and Aircraft Tracker.

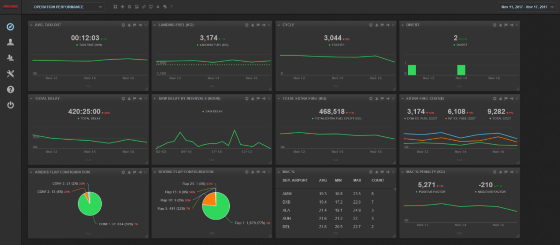

Pegasus Dashboard

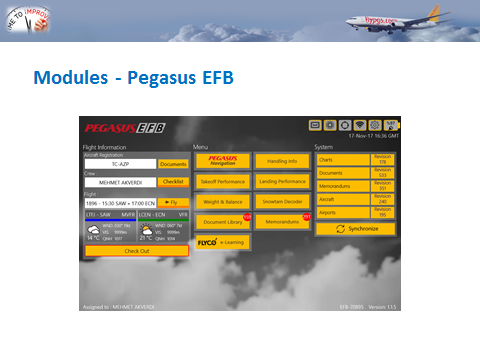

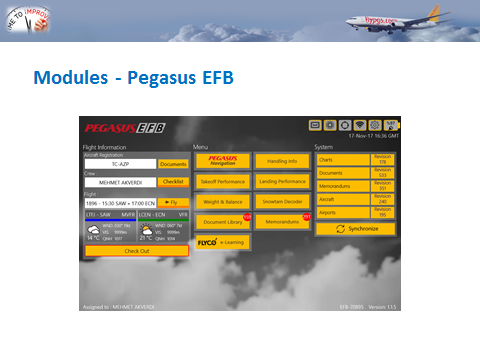

In figure 3, you can see the Pegasus EFB Main Page…

Figure 3

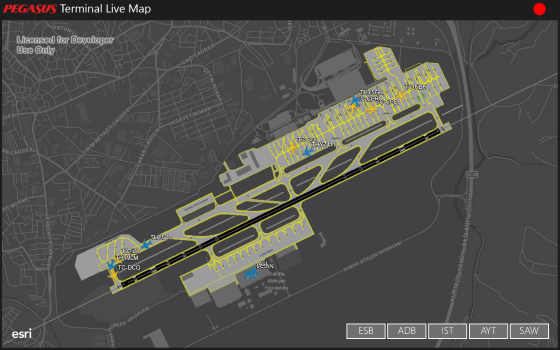

… with the various modules for pilots to use for flying efficiently and economically. The chart program is Pegasus Navigation and we also include with our charts visual approach, engine out procedures, etc. There’s handling information, take-off and landing performances, weight & balance, snowtam decoder, documentation… and one further module will be added, terminal live map, there are a lot of important things such as electronic signature, mass and balance calculations, electronic flight folders, technical log, and Operational Flight Plan (OFP). We are carrying only the QRH (Quick Reference Handbook) as paper on aircraft.

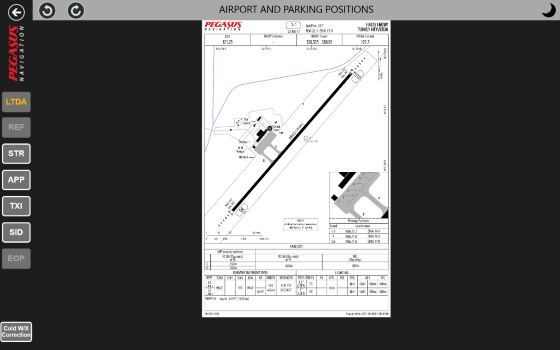

Pegasus Charts

Terminal Live Map

Flight plan screen

MODULES – PEGASUS EFB

Looking more closely at our modules, here are a few specifics.

Flight Module

There is an electronic version of the OFP, the eFlight Plan as well as an eLoad Sheet and eTrim Sheet plus an eVoyage Report. Also, pilots can ‘order’ fuel before they go to the aircraft so that, by the time they arrive onboard, the fuel is loaded and even if the pilot remains in the cockpit between flights he can use this facility.

Documentation Module

We have established a good specification for our pilots with a Versioning System and a High Speed PDF Viewer, plus we are publishing documents based on Airport or Aircraft so pilots can access the documents easily on their tablets.

Performance Module

Performance modules include take-off and landing performance, and weight & balance. This screen supports mixed fleets and we can show all performance calculations on the same page. There’s also live weather with the information filled automatically. Dispatch calculations can be made within ‘landing performance’ and there is a capability for In-Flight calculation also. It’s possible to add MEL (Minimum Equipment List) and CDL (Configuration Deviation List) for the aircraft before the flight plus take-off performance, calculate maximum take-off weight, assume temperature, etc. Also there are engine out procedures charts plus SID (Standard Instrument Departure) calculations – if the pilot selects SID, this module will offer the pilot the variance for using one engine out or SID procedure.

Take-off Performance screen

Handling Module

Also, the EFB offers handling information for pilots on approach and information about airports, with access to airport related memorandums as well as information about contractors and suppliers.

After the implementation, those essential EFB applications could be accessed more easily. Past flight plans were time consuming to prepare and approve whereas, with the new system, flight plans can be received through the system, be approved and then returned; all electronically. Performance calculations crucial to flight safety are also completed through the system and their accuracy (planned versus actual) can be monitored during the flight. Pegasus cockpits are now free of those heavy documents clearing cockpit space for the manuals that are mandated by the civil aviation agency and to keep important reference documents within easy reach.

BENEFITS

As a result of this program, Pegasus Airlines has gained some tremendous benefits in terms of safety, regulatory compliance, pilot workplace quality and, not to forget, savings.

The new system decreases the pilot’s workload and saves time by supporting faster aircraft turnaround times which is a very important benefit for a low cost airline such as Pegasus. Increased pilot efficiency has been another benefit gained from the new system with pilots focusing on their flight rather than on maintaining/completing the documentation or making calculations. And a further benefit has been improving onboard safety and efficiency of flying. This EFB solution pays its way as can be seen from the savings detailed below. Using the application we are able to track ground and air traffic movements live and in real time as well as follow our KPIs using the Pegasus dashboards.

Readers will understand when we say that any aircraft sitting on the ground is losing money; so one of our key objectives was to keep the aircraft flying. Pegasus (at the time when the new EFB was being developed) was achieving ten to eleven hours utilization per day but our aim was twelve hours. However, first we had to give the flight crew the right tools to improve safety and to reduce the workload, and to give them the time so that they could be faster when on the ground. Our standard turnaround time was 35 minutes, which we aimed to improve down to 25 minutes, towards which end our calculations now show we are achieving that, especially in Istanbul.

We feel that the program and the new EFB has achieved its objectives and that users are all happy with improved revenue and profitability: aircraft are flying more with 12.4 hours utilization at the last count. Using the dashboards, the airline management and board can see how much things have improved (and how much money we are making).

The Pegasus’ EFB project using the Panasonic Toughpad, stands out as a comprehensive cockpit software solution including tablet mounting, database, data connectivity tools, MDM, modules and support. It allows pilots to focus and work more carefully; pilots using EFB are kept up-to-date with quick and easy version based updates, and several applications can be run at the same time. When the flight map is open, the pilot can examine other documents, make take-off calculations and dynamically monitor runway conditions using Dynamic Runway to easily navigate to parking areas using the airport moving map. All necessary updates are delivered to the device online and no time is wasted trying to locate information among hundreds of documents. As well as the fuel saving from less weight in the cockpit, the EFB also supports low engine take-off to further reduce fuel burn. Overall, using the EFB has saved Pegasus €135,000 per plane per year (2016 figures); totalling around €11 million savings a year.

Document Viewer

SUMMARY

To close, readers can look at the following demonstration…

The program and development were still live at the time of writing with feedback emails through the EFB system on whatever topic the pilots wished to raise and the team could reply at any time; but more importantly, they could address whatever issue had been raised to improve the solution. As pilots work with the EFB modules, they can leave evidence of their completion of each stage and, once the flight has finished all of that information is transferred to a PDF file, a copy of the OFP. So if somebody wants to see what happened or the civil aviation authority wishes to inspect a flight, they need only to check the PDF file – there is no need for Pegasus to store a load of paper. It’s all in the servers and can be accessed anywhere at any time. All approvals remain as before but in electronic form plus, to meet EASA regulations, the system records who will be flying and who is monitoring the flight.

We hope this has given readers an insight into the EFB that we developed for ourselves at Pegasus Airlines using the Panasonic Toughpad. Readers can visit www.pegasusefb.com website for more details.

Contributor’s Details

Mehmet Akverdi

Mehmet AkverdiIn 2013, After graduating with honours in Avionics and Industrial Engineering, Mehmet started to work as aircraft performance engineer in Pegasus Airlines. He now has four years’ experience with Electronic Flight Bag (EFB), performance engineering, business intelligence and IoT (Internet of Things) systems in the airline industry. He has undertaken work related to aircraft performance engineering, software development, system integration, performance-based navigation and EFB solutions.

Capt. Korhan Celik

Capt. Korhan CelikCapt. Korhan Celik is assistant Fleet Manager of Pegasus Airlines. He has been involved in simulation and software projects simultaneously together with his flying career exceeding two decades. During realization and finalization of the EFB project in Pegasus Airlines, he contributed to the development phases of ‘electronic load and trim sheet’ and ‘electronic flight plan’ through EFB.

Pegasus Airlines

Pegasus AirlinesPegasus Airlines is a Turkish low-cost airline headquartered in the Kurtköy area of Pendik, Istanbul with bases at several Turkish airports.

Panasonic Toughpad FZ-G1

Panasonic Toughpad FZ-G1The fully rugged Toughpad FZ-G1 tablet with Windows 10 Pro sets the new benchmark for outdoor viewable tablets making it ideal for field workforces in outdoor scenarios. With its multi-touch display and digitizer pen, and flexible configurable ports, this device can be used to view high definition documentation and images in the field whilst benefitting from connectivity options to ensure data is always available when needed. The flexible configuration port gives users the legacy port options they require in a compact, fully rugged and lightweight form factor.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.