Articles

| Name | Author |

|---|

Less fuel, more efficiency, better service

Author: Jonathan Sanjay, Group Director Fuel Efficiency, AirAsia, and Andrew Jones, Airline Partner - Flight Operational Efficiencies, GE Aviation

SubscribeLess fuel, more efficiency, better service

Small savings and operational efficiency help AirAsia to ensure that ‘everyone can fly’ explain Jonathan Sanjay, Group Director Fuel Efficiency, AirAsia and Andrew Jones, Airline Partner – Flight Operational Efficiencies, GE Aviation

Where the program is going

Safety and operation efficiency are two of the most important issues at AirAsia as they are across the airline industry. And, with AirAsia, two objectives in this respect are to continue to be the largest low cost airline in the Asia Pacific Region and to ensure that costs are kept to a minimum so that, in the words of the airline’s motto, ‘everyone can fly’. However, to achieve these two objectives a fuel efficiency program is essential. In the past five years AirAsia has seen fuel prices increase by an average of 25% year on year. So the airline needs to do its best; be innovative and be passionate about reducing fuel consumption, towards which end they have taken on a sophisticated analytical tool from GE Aviation Flight Efficiency Services to reduce costs and, in turn, maintain demand for air travel.

From GE’s perspective, three things will make a difference for AirAsia operations and build on the technologies being deployed today by GE in support of the airline’s objectives as stated above. But first a cautionary note: it’s easy to be seduced by technology, the tools and big data; but it’s not all about the tools. It’s also important to remember the people who use those tools to make the decisions on which the airline relies day in and day out. As well as looking to the future, we can look back to Thomas Edison, founder of what is now GE, who believed in focusing on innovation, being prepared to not just invent products but, if it’s the right thing to do, to re-invent the company. Remaining true to Thomas Edison’s dictum, “… find out what the world needs, then… proceed to invent it,” GE still invests 5% of revenue into R&D. Today, that philosophy has been brought up to date with the Industrial Internet, an open, global network connecting people, data and machines: and that’s certainly being used in Flight Efficiency Services.

However, a business like GE Flight Efficiency Services is not at its best when acting alone. While the software business can bring technology, investment and innovation to the table, it is more effective in partnership with customers who share the same beliefs in terms of innovation and vision. Tony Fernandez, owner and founder of AirAsia, is helping GE Aviation to realize the vision with his own philosophy of “Dream the impossible, believe the unbelievable, and never take no for an answer…”

The objectives for GE Flight Efficiency Services include improved data security, better collaboration and better insights to equip the person at the ‘sharp end’ of an operation with the ability to make the right decision and be more effective. From an aviation standpoint, that means fuel efficiency, operational efficiency and safety.

What the program is doing

GE Flight Efficiency Services and AirAsia are working on two principle programs, fuel management and navigation services. Both programs are heavily dependent on the ability to access, analyze, interpret and reflect back the insights out of data to help, i.e. where are we; are we saving money and how much more could we save if we did something different? It’s all about architectures, profiles, benchmarks and big data analytics. What is important is for a solutions provider to deliver service such as fuel management in the context of a suite of services that goes across the board.

So for an airline, GE Flight Efficiency Services can deliver fuel management as part of a package including Flight Operations, Engine Services and change management. It’s also important that any program be long-term. It has helped that, before this current program, GE Flight Efficiency Services had been working with AirAsia for a long time over a range of collaborations supporting some mutual objectives. Time working together affords the room and the time to properly develop programs in a way that would not otherwise be possible. In this sense, AirAsia’s role as an early adopter and innovator puts them into a good position to help develop new approaches and services and puts GE Flight Efficiency Services in a good position to provide AirAsia with the latest tools and techniques as soon as they’re ready; to be first to use the new technology in the marketplace. It’s a symbiotic relationship.

Programs and areas covered

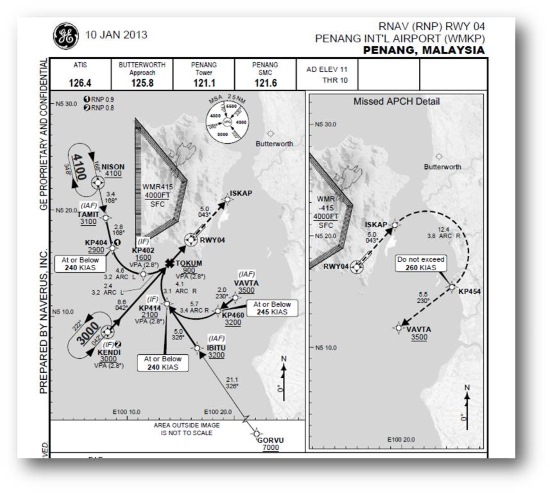

The first program to look at is using RNAV (RNP) procedures to deliver precision approaches for 15 airports in Malaysia (a first for Malaysia) and four airports each in Thailand and Indonesia. It’s not only about designing the procedures; it also involves helping AirAsia work through the operations specs to facilitate the regulator enabling them to operate RNP (Required Navigation Performance) procedures. The program is a great success so far and was predicated on delivering a number of things including track-mile savings and offering much more reliable access to all airports which can contribute to a reduction in the number of diversions or cancellations due to weather… so more predictability and reliability. Also, greater precision makes a significant contribution to operational safety with no need to run visual approaches into weather or terrain limited airports.

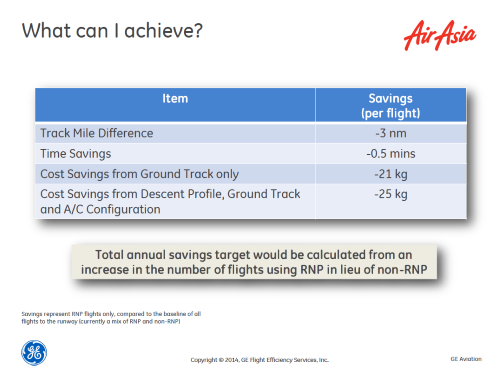

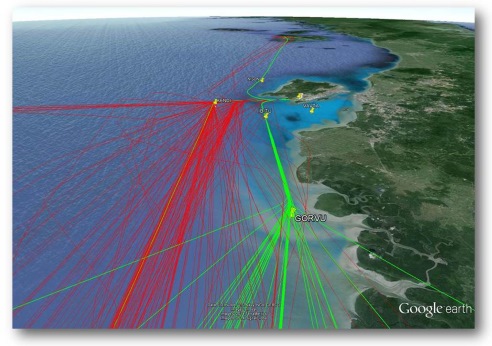

What AirAsia is doing around the RNP program

AirAsia’s first RNP flight in Malaysia was in October 2013 and the airline hopes to be first in Indonesia and Thailand to fly RNP procedures and first in Philippines. It also plans to get all its sister companies to fly RNP procedures in their base hubs having now been operating it for about a year across fifteen airports. About six months ago AirAsia asked GE Flight Efficiency Services to come up with a way to explain how much fuel really was being saved. The vendor tapped in to AirAsia’s own FOQA (flight operations quality assurance) data and came up with some interesting numbers showing significantly reduced track miles with RNP procedures. Comparing operations using RNP with the non-RNP operations from the past, it was clear that significant savings had been achieved (Figure 1)

The per flight saving numbers in Figure 1 might appear small but AirAsia operates 15,000 flights a month so small savings add up to big savings at the end of the day

The Pilot Portal

Pilots are key stakeholders in any fuel conservation program and operational efficiency initiative as you’d expect from them being, literally, at the sharp end of the business, operating the equipment. However, often the hardest thing about working with pilots is not so much introducing a new idea to them as getting them to let go of an old idea. It was a traditional change management challenge to help further the objectives of the fuel program, about creating a shared need, helping to shape a positive vision and getting that vision accepted and acted upon by pilots. It was important that they could understand the need to change, to do things differently; to mobilize some commitment and then implement the change and monitor its progress so as to be able to keep these key stakeholders informed of progress and results in the manner they prefer, with hard numbers.

In short, the idea was to make data and information that is relevant to pilots available to them as efficiently and easily as possible in a way that is clearly understandable, to keep them on board with the program. As always in managing change it was necessary to recognize the importance of those who might resist change if it was not properly communicated to them. Some of the information and data already considered above had to be brought to bear on the pilot community to which end, a report was generated that goes in a portal talking a little about what AirAsia feels is important to help pilots be better equipped to help meet the objectives and needs of the business.

The pilot portal was introduced taking data from the airline’s flight planning system and journey logs and putting it through the GE analytical solution so that every month a pilot can log on to his portal to get his own fuel management statistics compared with what his colleagues are achieving. He can also compare his compliance rates for a number of fuel saving actions such as idle reverse, one engine taxi… From this, pilots can benchmark how they’re doing compared to their colleagues, which has proved to be very motivating. It’s also tied into performance incentive calculations so that, at the end of the year, bonuses will reflect how much fuel individual pilots are saving.

Approach Procedure

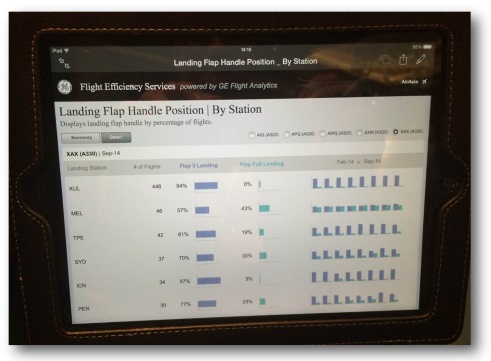

A more democratic approach to data distribution

It is essential for success that data is visible across all functions to try to avoid those silos that can be common in airlines. It is also important to deliver relevant information derived from millions of flight hours to enable effective control and decision support at the point of use. In this case, that was achieved by putting GE Flight Efficiency Services’ dashboard tool onto a tablet so that it could be available to whoever needs it with reports and report formats designed to be easy to read, easy to load, intuitive and where they are needed. In short, it’s all about getting the right information to the right person when they need it and in a format they can use. It enables pilots to, for instance, find out for an airport into which they are flying, the airline’s fuel statistics over the past few months. Information improves confidence and safety margins.

The pilot portal is also used for the airline’s instructor pilots so that when they’re conducting training flights, they can check their student’s performance on fuel management to identify areas where improvements would be possible.

Summary

As we said at the start of this article, it’s not all about the tools; it’s also about the people who use the tools and how the tools can help them to do a better job. Because it is the people using the tools, not the solution, who will actually save fuel for the airline. Using the tool, AirAsia has enhanced safety and operational flight plan accuracy so that what fuel is planned to be burned is close to what actually is burned, using all of the processes described above to improve pilot and dispatcher confidence. Operational efficiency has improved and fuel conservation plus the airline has ensured that many small savings will add up to big savings.

The task has been made more difficult for AirAsia having to manage six airlines in the group. But they’re well equipped to look out for deviations in operations. For instance, when the airline moved to a new terminal at Kuala Lumpur it was found that new procedures built by the ATC (Air Traffic Control) provider were very inefficient but AirAsia was able to use data from the new system to calculate what additional fuel burn the new procedure would cause and take that back to the ATC provider… it was a really powerful tool. The data is also fed back into the airline’s training program conducted for pilots and despatchers every month –providing real data and case studies.

Dashboard on a tablet

What’s next?

Where do things go from here? GE Flight Efficiency Services and AirAsia will be looking at innovative ways to collect and to look at data, harnessing that to improve the user experience, making it more intuitive to use, to save time and avoid confusion. None of this would be possible without advances in Cyber Security to ensure that democratizing data still keeps it secure. Similarly with Cloud Services, everything happens in the cloud for accurate, relevant, real time access for everybody who needs it. And, of course, in all this technology we mustn’t forget that the objective of efficiency in every area of operations is to ensure that everyone can fly.

Expected outcomes for AirAsia

- Save more fuel;

- Inform business decisions;

- Predict more opportunities

- Improve utilization & uptime.

Contributor’s Details

Andrew Jones

Andrew is a senior engineering and management professional with over 30 years’ experience and a proven ability to lead teams and to exceed client expectations in the delivery of complex solutions. He has diverse expertise including commercial management consulting, airport development, aerospace manufacturing, and aviation fuel and carbon solution management. He is expert in the use and implementation of fuel and energy management related initiatives.

GE Aviation’s Systems

With a broad range of avionics, power, and structures products, GE Aviation’s Systems portfolio is bringing the future of flight to today’s commercial aircraft. From Integrated Propulsion Systems that create unprecedented engine energy efficiencies to advanced flight management systems that enhance the capacity of the skies, GE provides the advanced technologies critical to superior aircraft performance and is poised to take civil aviation to the next level.

AirAsia

As a leading low-cost airline, AirAsia’s cost optimization philosophy is never at the expense of safety. The fleet of Airbus aircraft fully complies with International Aviation Safety conditions, and is regulated by the internationally renowned Malaysian Department of Civil Aviation. AirAsia has renowned partners for aircraft and engine maintenance, and makes significant investment to ensure safety, exercising zero tolerance to unsafe practices through training, work practices, risk management and adherence to safety regulations at all times.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.