Articles

| Name | Author | |

|---|---|---|

| Moving forward with a tablet EFB program | David B. Abbott, Director of Business Development, Avionics Support Group (ASG) | View article |

| Case study: Using a modern wind uplink | Bjorn Ostertag, Head of Fuel Efficiency & Punctuality Management, Lufthansa Cargo | View article |

| Case Study: Pegasus Airlines EFB: buy or build | Mehmet Akverdi, EFB Technical Admin, Pegasus Airlines and Capt. Korhan Celik, Assistant Fleet Manager, Pegasus Airlines | View article |

| Case Study: An iPad EFB Project at SmartLynx Airlines | Steinar Sveinsson, EFB Project Manager, SmartLynx Airlines and Jens Pisarski, COO, International Flight Support | View article |

| Getting the best from a paperless techlog | View article |

Getting the best from a paperless techlog

Author:

Subscribe

This article appears in Issue 32: the March/April 2018 edition of the Aircraft IT Operations eJournal. For your own free subscription to the eJournal – click on ‘SUBSCRIBE FOR FREE’ for full details.

|

GETTING THE BEST FROM A PAPERLESS TECHLOG

Gerrit Jassnowski, Project Manager Paperless Maintenance, Lufthansa CityLine and Udo Stapf, CEO, CrossConsense share the path to an Electronic Technical Logbook (eTL/eLB)

In this article we hope to offer readers an overview of Lufthansa CityLine’s implementation of an electronic TechLog. For ease of understanding, we’ll break the whole project into manageable steps but first, a profile of the airline that is the subject of this case study.

LUFTHANSA CITYLINE

Lufthansa CityLine is a wholly-owned subsidiary of Deutsche Lufthansa AG serving around 80 destinations throughout Europe and around the world with a fleet of Embraer 190/ -195 and Bombardier CRJ-900; as well as Airbus A340s on behalf of Lufthansa. The airline operates up to 330 flights daily out its Munich and Frankfurt hubs. The home base is located in Munich and together with the line station in Frankfurt and the base maintenance location in Cologne about 2200 employees work for the company. Every year, Lufthansa CityLine flies some 8 million passengers.

THE eTLB PROJECT

In 2015, at the culmination of a two-year project, Lufthansa CityLine implemented AMOS as its main MRO system. After some adjustments and with the stabilization of the system, the airline decided that it was the right time to replace the traditional paper Technical Logbook with an electronic solution. But, before anything further steps were taken, some minimum requirements were established.

- Because of the small cockpit size on existing aircraft, compatibility with already existing hardware was important.

- As Lufthansa CityLine does not currently have in-flight connectivity, the solution had to be one that does not require constant connection to ground.

- It clearly made sense that, as AMOS was by then the Lufthansa CityLine MRO system, any eTechLog solution must be able to interface with AMOS.

- Processes around the TechLog at Lufthansa CityLine are optimized around short flights and short turnarounds so the new eTechLog had to be able to be integrated with these approved and proven processes.

- Because all operators within the Lufthansa Group are considering electronic TechLogs, the solution would have to be one that could be used across the whole Lufthansa Group.

- Any solution would have to be easy-to-use for pilots and maintenance engineers; intuitive and able to be used without extensive training to open and close complaints.

- The solution should be compliant with EASA regulations.

- Because of the cockpit size (see above) it should be possible for maintenance staff to finalize documentation without entering the cockpit or interfering with the boarding process or the preparation of the flight.

STRATEGIC TARGETS

Lufthansa CityLine went into this project with some specific ideas on gains they wanted to realize. These can be seen in the strategic targets set for the project.

The first target was to reduce the workload. The old manual system required complaints to be entered into the TechLog by the crew and also entered into the ACARS (Aircraft Communications, Addressing and Reporting System) system for transmitting to the CAMO (Continuing Airworthiness Management Organization). On the maintenance side it was the same with every complaint needing to be written down in the paper book and, later on, entered into AMOS. Either way, every complaint had to be reported twice.

Looking at the process from an environmental point of view, it would be in everybody’s interest to save paper and Lufthansa CityLine will be able to save up to 2 tons of paper each year by using an electronic TechLog. Also, in the old system, the hard copies were sent to a scanning center for conversion into a PDF format for archiving. Lufthansa CityLine wanted the new solution to eliminate both the hard copy papers and the need for a separate electronic archive and the costs of these processes can be nearly eliminated by using a wholly electronic solution.

Especially on the maintenance side there has always been a gap in the data transfer into the AMOS System, so aircraft status on the CAMO side in the system was not really up-to-date. Also, one obvious reason for using an electronic solution is the elimination of human errors such as readability or mismatches. The problems with unreadable documents will be familiar to readers. One objective was to improve data quality by loading complaint templates into the system so that, for example, an ATA chapter would be pre-built by use of mandatory fields. Documents in the old system were 100% quality checked in the quality department prior to dispatching to the archive whereas that process can also be reduced by use of an electronic solution. And, as mentioned above, the delayed entering of data into AMOS was previously compensated for by a high level of telephone communication which can be reduced with a real-time and up-to-date record of the aircraft status in the system.

The new solution has enabled Lufthansa CityLine to reduce the workload in this by half which, in turn, saves up to €250,000 per year.

THE SOLUTION

Taking all that into account, Lufthansa CityLine settled on the CROSSMOS solution for a number of reasons. First, the system is already in use with a successful two years track record at SWISS International Air Lines. It’s also a system based on standard processes and is flexible which means, for Lufthansa CityLine, Maintenance can connect the devices on the aircraft master devices, creating the opportunity to deal with issues raised without the need to be in the cockpit. Also, CROSSMOS safely complies with EASA regulations and uses the standard AMOS interface (CrossConsense has been working with Lufthansa CityLine for some years, hosts the airline’s AMOS and provides system support). One further key point is that CROSSMOS was seen to be compatible with Lufthansa CityLine’s proven and approved TechLog processes.

INSTALLATION

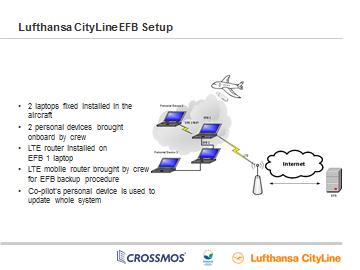

Next, Lufthansa CityLine checked the possibility of integrating the eTLB into the existing EFB infrastructure (figure 1) to avoid having to install additional hardware in the cockpit.

Figure 1

Currently, the EFB includes 2 fixed laptops installed on each aircraft, each with its own monitor. Crews bring their personal devices into the cockpit which use Windows Surface Pro. On EFB Laptop 1 there is an LTE (Long Term Evolution /) router installed that is automatically activated and de-activated according to ground speed. This router establishes Wi-Fi in the cockpit as well as connectivity to the ground server. In addition to this, the crews bring one mobile router to act as a back-up in case of the failure of EFB 1 or its router. And the co-pilot’s personal device is used to update the entire system.

Although this EFB infrastructure is not revolutionary, it is reliable with the opportunities for back-ups that were also needed for CROSSMOS. So Lufthansa CityLine decided to implement the CROSSMOS eTLB into the existing EFB infrastructure (figure 2).

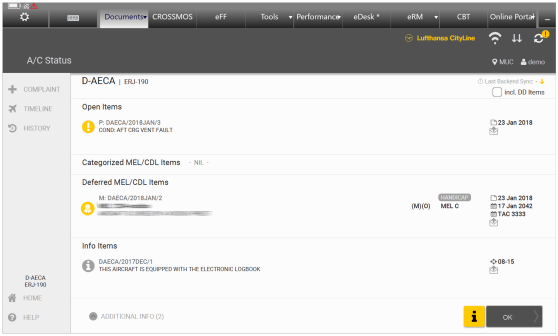

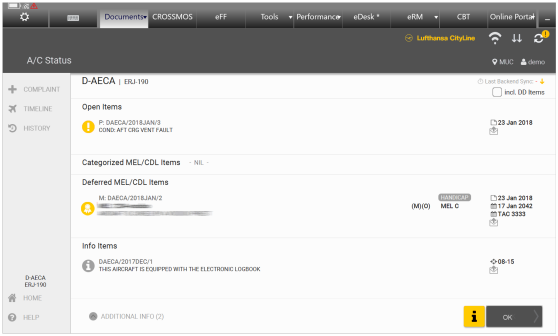

Figure 2

EFB 1 has also been designated the master for the electronic TechLog. The connectivity and synchronization is established by the fixed and installed router. EFB 2 serves as a back-up and as master in the event of a failure of EFB 1. Synchronization can then take place using the mobile router. Maintenance will connect their devices into the master device through logging in to the Wi-Fi established by the router. And since Lufthansa CityLine has not been using a cabin log for more than fifteen years, all complaints are entered into the technical log book so there’s no need to implement a cabin log book at the outset.

PROJECT TIMELINE

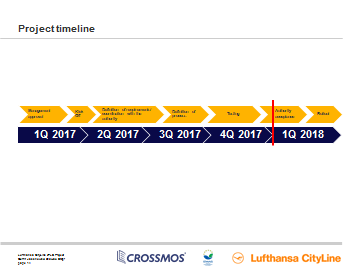

Figure 3

Figure 3 shows the project timeline and associated milestones. In January 2017, management approval was given to start the project following which the specifications of the airline’s requirements were established with the definition of the project plan and set-up of the project team. February saw a kick-off meeting with the whole team, including CrossConsense, and the then current paper TechLog process was compared to the CROSSMOS eTLB process which culminated in a new eTLB process flow. It was also decided how the change management would be achieved through regular meetings and newsletters and, looking to the end of the project, a simple and efficient training program was developed using a short introductory video for cockpit crew, to be available through the EFB at any time; while, on the maintenance side, there was a short training program using CBT (computer based training) and, on the aircraft, through key users. The final step, and still pending at the time of writing, was approval by the authority. The roll-out was originally planned for December 2017 but was postponed to Q1 2018 for two good reasons. That pending approval from the authority is one reason while the other is the need to get the software onto all aircraft EFB systems which has to await the regular EFB updates scheduled for Q1 2018.

CHALLENGES OF THE PROJECT

The most important challenges have been the implementation of the electronic signature and to get approval for the solution from the relevant authority – the German Federal Aviation Office (LBA). Another challenge was to establish the change management project – employee mind sets and concerns regarding the collection and use of electronic data have to be taken seriously and addressed so that they can use the new system with confidence. And, of course, the new system must remain in compliance with all relevant authorities’ regulations. For Lufthansa CityLine, it was also important to establish and maintain standards within the Lufthansa group; so, all adaptations and modifications of the system had to be discussed within the Group. Furthermore, it was important to have a stable and safe process for login and for the signature. Finally, one of the most challenging aspects was completing the project within the tight timeline set.

BUSINESS CASE

The business case on the cost side was based on the investment in the software license and for the operational fees for the software and interfaces. On the savings side, the project took into account the savings on the paper books and the improvement in efficiency for the maintenance engineers as well as the reduced archiving costs. The calculations were very conservative, taking into account items that were, in the event, no longer needed. Even with those higher costs, that cost is projected to be amortized over three years, until early 2020.

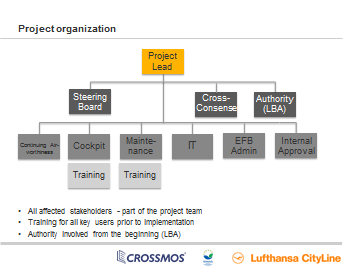

PROJECT ORGANIZATION

Every project needs an organization to manage the project and its relations with the wider business. The organization to manage the eTLB project in Lufthansa CityLine can be seen below (figure 4).

Figure 4

It was felt to be important to have all affected stakeholders represented within the project team and all team members continued with their normal jobs as well as the project. In the middle of the project (see figure 4 above) all key users were given training prior to implementation plus, one of the first tasks was to involve the regulatory authority.

GETTING APPROVAL BY THE REGULATORY AUTHORITY

Lufthansa CityLine are the first commercial operator in Germany applying an approval to use an electronic TechLog (eTLB) solution. Another issue that had to be dealt with was that there was a special law in Germany for handling signatures, i.e. replacing a hand-written signature with an electronic one. This law was superseded by an EU directive in 2014 and expired on 29 July 2017. Fortunately, Lufthansa CityLine and CrossConsense worked closely together to ensure compliance with the regulations and CROSSMOS was already approved by EASA in relation to the implementation at Group company SWISS International Air Lines. That said, the authorities were involved in this Lufthansa CityLine project from the beginning, discussing the scope of the project. A CAME draft of the new electronic log book was available for the authorities and the LBA came forward with some requirements and comments during the course of the project. Those requirements were taken into account by Lufthansa CityLine and the changes reported back to the authority.

In October 2017, CAME (Continued Airworthiness Management Exposition) approval was requested. At the time of writing, a final meeting with the CAMO auditors with a full demonstration of the system to the authorities and the approval were still pending.

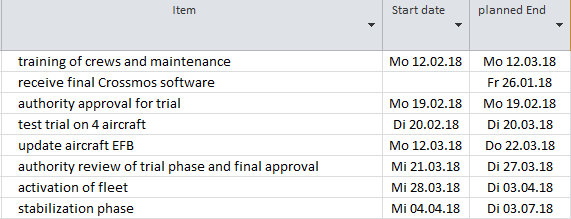

ROLL-OUT PLANNING

The plan at the time of writing was to commence training with the new eTLB solution at the Q1 2018 (figure 5) and to receive the final software from CossConsense by the end of January 2018 so that it can be sent to Lufthansa EFB Support Team in Frankfurt.

Figure 5

Lufthansa CityLine discussed with their authority a trial using four aircraft over four weeks starting in Q1 2018. There was planned to be a review with the authority after the trial phase in order to get final approval following which the fleet will be activated and move on to the stabilization phase over several months, during which the paper based technical log book will remain on board aircraft as a back-up in case of unforeseen problems.

FUTURE AMBITIONS

Although the Cabin Log is not going to be used at the outset there is still an interest in adding that in to the system at a later date. Also, once CROSSMOS is up and running, the Dent & Buckle chart from AMOS will be loaded to the system along with some other technical documents plus there is a plan to improve the use by connecting personal pilot devices. Looking further ahead, Lufthansa CityLine will work with CrossConsense and the wider Lufthansa Group to continue to improve the solution. Finally, Lufthansa CityLine has a project to introduce in-flight connectivity which, when it has been implemented, will also be used for the eTLB.

We hope that readers have found this outline of the Lufthansa CityLine eTLB project useful.

THE eTLB PROJECT AT CROSSCONSENSE

CrossConsense took the decision to develop an electronic Technical LogBook in 2013. The developer and solution vendor had been working with AMOS implementations for 15 years but wanted to also develop a CrossConsense product. As a start, about 150 user stories were collected as the basis for workshops with airlines, stakeholders and authorities, at which CrossConsense presented its thoughts, up to that point, on an eTLB solution. Based on the outcome from those workshops, CrossConsense developed a flexible eTLB solution, CROSSMOS, and, in early 2016, the first implementation went live with SWISS International Air Lines. Since then, Edelweiss has gone live with CROSSMOS in April 2017 and contracts to implement the solution have been signed with other airlines including Air Dolomiti, Deutsche Lufthansa and, of course, Lufthansa CityLine, the subject of this case study.

Because of the close affinity between CrossConsense and AMOS, people sometimes assume that CROSSMOS is an AMOS related solution, but it is not. The name CROSSMOS is derived from ‘CrossConsense’ and the word ‘Cosmos’, a term that stands for unlimited possibilities for interfacing.

The goal was always to develop a standard software solution; CrossConsense never wanted to have a stand-alone solution for one airline or one customer but rather wanted to develop something that could be used by any customers.

The developers feel that CROSSMOS can be considered a standard solution because the development started with 12 airlines and the authorities who participated in the two-day workshops (see above), saw the ideas that CrossConsense had on the subject of eTLB, and contributed their own thoughts to discussions which led to some desirable features being agreed and refined in later monthly calls. The whole development used agile methodology (figure A). There are two main ways to develop software. The ‘Waterfall’ method is where the developer collects a catalog of requirements, develops the software and presents it to the customer who might say ‘yes’ or ‘no’ – which could turn out to have been a significant waste of resources. ‘Agile’, on the other hand, is where the customer (users) participates in the development process with regular involvement and changes during the development where necessary – a methodology that anticipates the need for flexibility and applies a level of pragmatism into the delivery of the finished product. With this, there is a very high likelihood of acceptance by the customer, which means a very low likelihood that money will be wasted.

Figure A

Around CROSSMOS

There are a number of functionalities around CROSSMOS but an essential feature is that it does not interfere with a user airline’s current back office; rather the eTLB solution works with the back office supplying data that can be used in a number of ways. So, there is only one source of data for users to maintain. There is a good enterprise service bus (ESB) available which allows users to collect and map data to all back-end systems on the market today. The system currently interfaces with AMOS and with SAP but is able to interface with other E&M systems a customer airline is using. A rule engine is available where users can set-up workflows, perhaps related to a specific issue raised by a pilot but that has a wider application or perhaps to ensure that some data goes to a specific system. Computer based training (CBT) is offered with the solution for pilots, cabin crew and maintenance personnel. Associated apps have also been developed such as ‘Aircraft Status’ where the pilot can see the aircraft status even while he is in the briefing room. And there is an advanced trouble shooting system called ACSIS that can be connected with CROSSMOS and helps users to better manage the aircraft.

At the time of writing, SWISS International Air Lines had performed about 120,000 flights using CROSSMOS, of which some 2,360 flight had had no connectivity so had to use a back-up solution (for SWISS that is a USB stick) for the legal ‘leave data on the ground’ process. That meant that more than 117,000 flights were able to use a regular sync process (98% connectivity reliability) with an average synchronization time of 20 seconds.

Contributor’s Details

Gerrit Jassnowski

Gerrit JassnowskiGerrit Jassnowski is Team Leader for Airframe & Systems Engineering with Lufthansa CityLine. He began his career as an aircraft maintenance engineer at Lufthansa in 1990. In 1993 he moved to Augsburg Airways and 1997 to Lufthansa CityLine. In 2014, he completed his bachelor’s degree in professional aviation and became team leader in the MCC. In 2016, he became responsible for implementation of paperless maintenance and ELB and, in 2017, completed his master’s degree in technical management. He now leads the team responsible for aircraft systems and structure for the Lufthansa CityLine regional fleet.

Udo Stapf

Udo Stapf is the founder and CEO of CrossConsense, based in Frankfurt, Germany. Since 1990 he has been working in the aviation industry, starting as an aircraft line and base maintenance engineer and AMOS integration specialist. After he completed his degree as a business economist he worked as a logistics manager for a German charter airline until he founded CrossConsense 2002.

Udo Stapf is the founder and CEO of CrossConsense, based in Frankfurt, Germany. Since 1990 he has been working in the aviation industry, starting as an aircraft line and base maintenance engineer and AMOS integration specialist. After he completed his degree as a business economist he worked as a logistics manager for a German charter airline until he founded CrossConsense 2002.

Lufthansa CityLine

Lufthansa CityLineLufthansa CityLine is a wholly-owned subsidiary of Deutsche Lufthansa AG specializing in hub-feeding services for the global Lufthansa network in Frankfurt and Munich. Lufthansa CityLine employed about 2200 people (as of December 31, 2017). the airline carried some 8 million passengers. The fleet consists of 50 modern and environmentally compatible aircraft of Airbus, Embraer and Bombardier types.

CrossConsense

CrossConsenseFor the last 15 years, CrossConsense has become a known name in the aviation industry especially in the fields of AMOS consulting, support, hosting and operation. In 2012 CrossConsense started to develop – in collaboration with 11 of its airline customers – CROSSMOS, an electronic technical logbook with state-of-the-art methods and technologies. CROSSMOS aims to become the standard electronic TechLog solution and can be connected to other back end MRO systems.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.